For more than five decades,

Meclostampi Group, based in Northern Italy, has carved out a legacy in progression toolmaking. Founded in 1971 by Cavaliere Antonio Canobbio and now led by his son Valter Canobbio, the company has remained steadfast in its philosophy — quality must always trump cost.

Valter, whose approach to investment is unapologetically pragmatic, said: “We are toolmakers, and we produce tools for many different fields, but our main market is automotive. In my opinion, it is a short-sighted thing to buy the cheapest machine tool solution, because the parts produced are only as good as the quality of the machine — this is also true for the service.”

This guiding principle has shaped Meclostampi’s long-standing partnership with

R.F. Celada SpA and its commitment to Sodick EDM technology, a relationship that began in 1988. Operating out of a 7,000m

2 facility in Lomazzo, Lombardy, and employing over 80 skilled professionals, Meclostampi has become one of Europe’s premier manufacturers of high-precision sheet metal press tools.

Sergio Nava of Celada highlights the synergy between the companies. Sergio Nava said: “Meclostampi manufactures high-quality products on their Sodick machine tools. Incorporating a high level of technology and performance that is blended with the expertise of the Meclostampi staff, the level of performance and the products which Meclostampi is producing is incredible. We are going in the same direction, and the target is to keep a high level of Meclostampi product quality, but also Celada support.”

One of the most transformative aspects of Sodick’s technology has been its ability to overcome the challenge of machining carbide. Valter explained: “In the past, it was always a challenge. However, for Sodick, it was not a problem like it was with other machine tool brands. In the past, working with carbide resulted in surface issues, but Sodick solved this problem many years ahead of its rivals.”

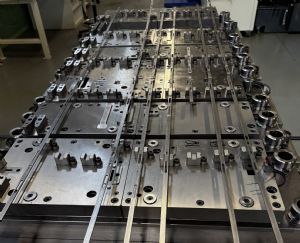

Meclostampi’s current portfolio includes multiple ALC600G and SLC600G wire EDM machines, alongside an AG60L die-sinker. These machines are equipped with Sodick’s proprietary rigid linear motor drives, offering significant advantages over traditional ball-screw systems. The ALC600G, for instance, integrates advanced generator technology and i-Groove functionality to enhance surface finish, precision, and wire efficiency. With cutting accuracies of ±3µm and surface finishes as fine as Ra0.20µm, these machines are built for uncompromising precision.

The SLC600G pushes the envelope further with Sodick’s Smart Linear and Smart Pulse technologies. Its SPW generator delivers faster cutting speeds and superior finishes, while the 19-inch touchscreen and Q3vic programming software simplify operation and reduce setup time. Both models come with Sodick’s 10-Year Positioning Accuracy Guarantee—a testament to the reliability and longevity of their linear motor systems. Warwick-based

Sodi-Tech EDM Ltd is the exclusive distributor of Sodick products in the UK and Ireland.

For Meclostampi, reliability is not just a factor — it is critical. Valter said: “In my mind, I don't remember a stoppage of my Sodick machines for maintenance or service. Only with the best machine on the market, can we give the customer the best solution.”

Operational dependabilityThis operational dependability is key to Meclostampi’s dual role as both toolmaker and stamping specialist. With presses ranging from 250KN to 6,000KN, the company can test its tools under real production conditions. Valter Canobbio explains, “With our stamping department, we can see the life and quality of our tools. If we make tools with the right accuracy, it means longer running time, and this is something we can test directly in our department.”

The company’s focus on automotive tooling demands exceptional standards. Meclostampi produces progressive dies, transfer tools, and deep drawing tools for leading automotive manufacturers. Their patented mechanical threading units are exported to over 25 countries, underscoring their global reach.

Sodick’s machines also align with Meclostampi’s environmental goals. Modern models incorporate energy-saving technologies that reduce power consumption by up to 60% compared to conventional EDM systems. These savings stem from innovations in pulse generation, linear motor efficiency, and intelligent power management—critical for high-volume operations.

Looking ahead, Meclostampi sees no reason to change course. Valter Canobbio says, “Our policy is to follow the best technical solution. From what I have seen during the last few years with Sodick and their constant improvement, it would be nonsense to change our technical solution now, as the machines are always evolving. So, for us, Sodick are our partners for the future.”

With Industry 4.0 capabilities such as LAN connectivity, remote diagnostics, and predictive maintenance, Sodick machines are future-ready. These features allow Meclostampi to integrate EDM operations into broader digital manufacturing ecosystems, ensuring uptime and performance through proactive support from Celada’s service team.

The enduring partnership between Meclostampi, Celada, and Sodick exemplifies how strategic investment and collaboration can elevate manufacturing excellence. Valter concluded: “Speed, accuracy, reliability and flexibility are essential when creating quality press tools, so making the right investment in equipment is key.”