US-based

King Machine has firmly established itself as a global leader in tyre mould production, supplying major international tyre manufacturers with precision-engineered solutions for everything from high-performance and winter tyres to heavy-duty truck applications.

King Machine’s CEO Michael Wells, underscoring the company’s commitment to quality, said: “We want to ensure that the mould is absolutely perfect — because only then does the tyre have a chance to also be perfect.” Speed to market is equally critical. Harrison Walston, executive vice president, said: “Our goal is to deliver our products first so that our customers can bring their tyres to market ahead of the competition.”

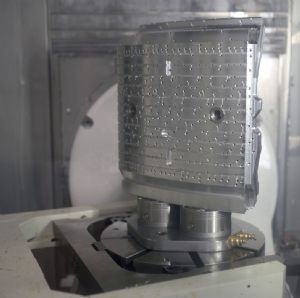

To achieve this, King Machine has adopted a dual machining strategy, investing in Grob’s five-axis G350 universal machining centre for segment production and a G550T mill-turn machining centre to manufacture the sidewalls. Furthermore, both machines are integrated with Grob’s pallet storage system, enabling round-the-clock, scalable production. Mr Walston explained: “We wanted to make sure that everything we do moving forward is fully integrated with the right automation. We wanted scalable production that could run round the clock — and Grob’s automation solutions make that possible.”

The appeal of Grob’s integrated approach is clear. He added: “What I really like about Grob is that everything comes from a single source. We don’t need to install extra coolers or chip conveyors — it is all part of a fully integrated product.” This consolidation of machining steps has led to significant efficiency gains. Mr Walston continued: “We eliminated entire operations and setups. Our operators basically only need to load raw material.” With most programs running only once, the process is streamlined, as Iulian Arsene, director of engineering, explained: “We program the machine, start the process, let it run overnight — and the part is finished the next day.”

Precision is keyThanks to the unique kinematics of the Grob machines, even large workpieces are handled with ease. Precision is key, so King Machine has raised the bar with integrated measurement systems like the Blum laser. Mr Arsene explained: “Today we achieve tolerances of 25 to 30µm. Tools and reference points are set directly in the machine — giving us the highest level of consistency and security.”

The switch to Grob has also delivered a technological leap. Mr Arsene added: “Previously, we worked with several manufacturers. With Grob, we were able to virtually test our parts for the first time and ensure the machine met our requirements. Now we produce faster, more accurately, and with less human intervention — the quality has improved significantly.”

Fully automated production has become a defining competitive advantage. Mr Wells continued: “The surfaces we achieve are exceptional — so good that you almost want to hang the parts on the wall rather than put them in the press.” The result is a dramatic acceleration in delivery times. He added: “For our customers, it is not just about cycle time — it is the time from order to delivery that counts. With Grob automation, we can minimise this time and secure a clear market-leading position.”

Support from Grob has been another cornerstone of success. Mr Arsene said: “Whenever we had a problem — whether machine downtime, maintenance, or engineering — we could always rely on support. There was always someone on the line ready to help immediately.”

Looking ahead, King Machine sees its partnership with Grob as essential to its long-term strategy. Mr Wells concluded: “We want to further expand our market leadership in North and South America — and Grob is now a central part of that strategy.”