Alloyed Ltd

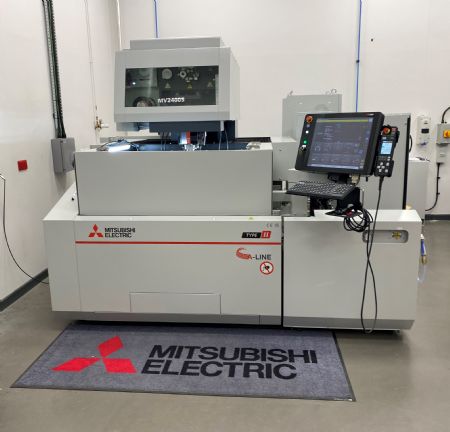

Alloyed Ltd, an industry-leading design, development, test and production facility for additively manufactured (AM) products, recently installed a new Mitsubishi MV2400S Type II wire EDM, supplied by the Wellesbourne-based

Engineering Technology Group.

Borne out of a merger between OxMet Technologies and Betatype in 2020, Staffordshire-based Alloyed delivers a mixture of capabilities for digital metal applications from the development and production of customised alloys for traditional and AM manufacture, process optimisation and control, through to the production of metal parts.

The company separates its business model into three different segments, the industrial division delivers solutions for aerospace, motorsport, space, automotive customers and more, the electronics division develops next-generation technologies with world-leading brands through AM and the medical division works with surgeons to design and manufacture customised orthopaedic implants.

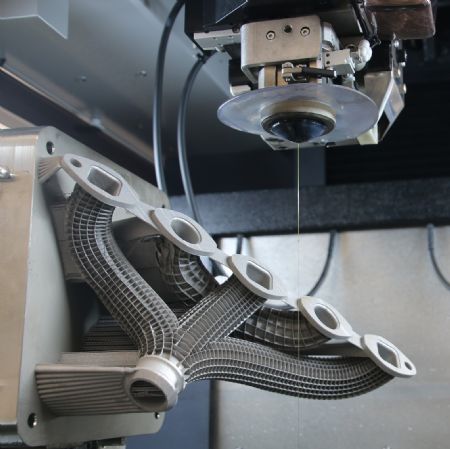

With a complete suite of Renishaw metal additive machines, one area that was causing a bottleneck was an unreliable wire EDM machine used for removing parts from base plates following 3-D printing. With the existing EDM machine, issues included constant wire breakages and the resultant manual re-threading, unreliable wire performance, water tank leakages, and a G-Code programming CNC interface that was difficult to operate and integrate with other technologies on-site.

One of the most difficult issues for Alloyed was the frequent wire breakages that would stop the machine mid-cutting cycle. Without an operator constantly present, the company would never know if the machine was in-cycle or awaiting operator intervention – losing countless production hours.

Dr Stephen McCain, the machine and systems manager at Alloyed (pictured above), said: “With an opportunity to manufacture titanium 64 AM parts on a production scale, we started asking sub-contract manufacturers with wire EDM capacity to see if they could cut details on the thin-walled parts as well as cut them from the base blocks — this was a trial in the capabilities of their EDM machines more than individual skillsets.

However, when Alloyed spoke to ETG’s resident EDM expert Scott Elsmere, it soon became clear that the Mitsubishi MV2400S Type II wire EDM was the perfect solution. It was ordered in April and delivered in May and incorporates Mitsubishi’s intuitive AD Series CAD/CAM system – a feature that has instantly slashed programming times.

Mr McCain said: “We can export STL files and any other CAD files into the new Mitsubishi wire EDM and it eliminates most of our programming problems. We load the CAD file to the machine and it automatically programmes the job. It detects what part of the component requires processing and it selects the machining parameters with some very simple data input. For us, we just ‘press play and walk away’.”

For any jobs that may require programming on the machine itself, there is a user-friendly 19in display interface. He continued: “The functions are extremely easy to understand with intuitive diagrams that guide us through the process. We recently needed to cut some precision shims and a sub-contractor wanted to charge us £50 per shim — we clamped a batch of shim material together and programmed and machined them on the EDM in minutes. I now have a lifetime supply of shim and it has barely cost us anything!”

“What has also been useful here is the support of ETG. Not only did ETG supply complete training on the machine and the CAD/CAM system, but they also wrote a lot of our programs and tested them for us. The service has been remarkable.”

Productivity Alloyed says that the programming of each job is now more than 75% faster than on the previous wire EDM machine. It gives the shopfloor staff greater confidence when programming and they can easily draw shapes as per their requirements.

Mr McCain continued: “We can enter the material type and our desired surface finish and the AI technology in the machine control will remove the ‘trial and error’ approach. If we require a surface finish of Ra0.3, we input that into the control - the cutting data and number of passes will be determined by the control system itself. It even governs the speed of the wire automatically by constantly determining the material thickness changes throughout the process. This increases our productivity times by around 40 to 50% compared to the previous machine.”

Alloyed additively manufactures components from a multitude of materials, including aluminium and nickel-based alloys, steel, bone alloys, metal matrix composite, copper and even platinum. With such a diversity of materials that are continually being tested, the company makes plates of test cubes in different dimensions for stress, tensile, hardness testing and even CT scanning.

A typical test plate may consist of 10 rows of printed cubes – with the new Mitsubishi MV2400S applying its AI technology, the cutting time has fallen from one hour to less than 25min. This typifies the productivity saving achieved with the new EDM machine. However, the productivity and programming benefit don’t tell the whole story.

One of the largest savings for Alloyed is eliminating manual intervention that was continuously required to re-thread the wire each time it broke – each re-thread would take between 5 to 15min. A short intervention may not be considered too much of an inconvenience, but when the wire continually breaks – it turns into a major issue.

For example, the frequently produced plates of test cubes that are efficiently machined 50% faster on the new Mitsubishi would require 8-10 wire rethreads with the previous machine. Manually re-threading the wire 8-10 times at a minimum of 5min per re-thread was adding a minimum of 40min to a job that only required 1hr of cutting.

Alluding to this, Mr McCain said: “The Mitsubishi MV2400S has an outstanding automatic wire re-threading system that gives us the confidence to walk away from the machine and leave it to run. Our team members will run a number of machines simultaneously – being present on one machine consistently isn’t how we work. The automatic wire re-threading can even be conducted when cutting a large job with a considerable distance between centres.”

With a new annealing system that reduces the wire curl ratio to less than 10% and a wire break point insertion for thick workpieces, precise automatic wire re-threading is assured. Furthermore, this is complemented by other precision features such as linear shaft motors and optical drive systems to create a circular accuracy of 1µm.

Mr McCain concluded: “Above all, we trust the new Mitsubishi machine. It is precise, reliable, accurate, easy to use and it is a machine that we know we can set up and leave to run. Wire breakages will no longer disrupt production as the Mitsubishi will just automatically re-thread the wire and continue.

“We are now working with ETG on new workholding solutions and possible automation integration for production purposes if the need arises. We are also looking at purchasing more Mitsubishi wire machines for some of our other facilities too.”