Just a short distance from Silverstone, Daventry-based

JRM Group specialises in the design and bespoke manufacturing of solutions for the automotive, motorsport, aerospace, marine and medical industries. The company also has a racing division that has progressed through rallying, FIA GT1 and the GT3 endurance competition. It was back in 2017 when the ISO:9001 company invested in its first five-axis machine tool that it realised a high-end CAM system was also required.

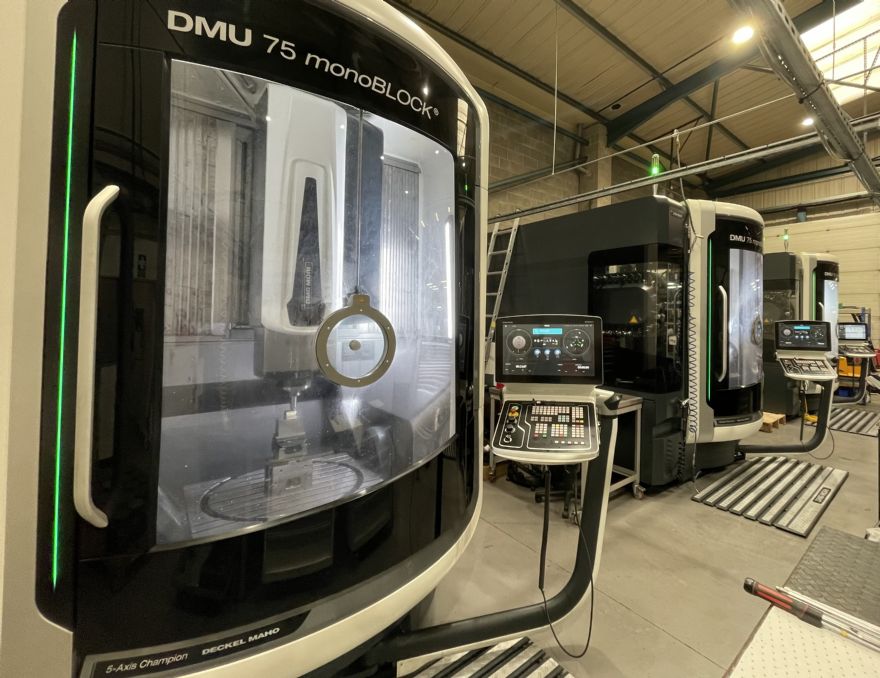

The current plant list at the JRM Group includes a range of manual and CNC turning and milling centres and more recent investments include a DMG Mori LaserTec 30 SLM additive machine and a CLX450 turning centre, but it was the arrival of its first of three DMU 75 monoBLOCK five-axis machining centres that demanded a high-quality CAM solution. This is where

Open Mind Technologies entered the fray with its industry-leading hyperMILL CAM system.

Mike Sutton, a CNC machinist and programmer at JRM Group, said: “JRM needed to progress its machining capabilities into five-axis machining and also realised the existing CAM package was limited to three-axis machining. Undertaking due diligence with a complete review of the marketplace, we opted for hyperMILL and this decision was influenced by the realisation that a lot of our motorsport customers and F1 teams were already hyperMILL converts. Our experience of hyperMILL has been fantastic.”

The 40-employee company manufactures everything from prototypes and small batches for the motorsport, aerospace and defence industries to jigs, fixtures and 3-D printed components, processing a wide variety of materials. The closest the JRM Group gets to production machining is a five-part wishbone assembly for a high-performance sports car customer in Germany that requires several hundred assemblies a year.

Looking at the wishbone components produced on a five-axis DMG Mori machine, Mr Sutton explained: “We are currently using a cycle in hyperMILL called arbitrary stock removal, machining 25Cr 04 steel with a 40mm high feed face mill. The tool is running at an 8m/min feed rate with 0.5mm cuts and 50% of the tool diameter, which is pretty fast. We have the machine running at 80% rapid and feeding at 8m/min. The 0.5mm cut was recommended by the tool manufacturer as the way to machine with high-feed cutters is to take small depths of cut at high speed. This is different to trochoidal milling where you take larger depths of cut with a smaller radial value.”

Improved machining strategyWhen programmed with an alternate CAM system, one of the wishbone components had a cycle time of 4hr. By adopting strategies such as arbitrary stock removal in hyperMILL, JRM has improved the machining strategy and cut the cycle time from 4hr to 3hr and 5min. The 25% saving per part is impressive, especially when considering the company produces hundreds of wishbone parts a year. The savings are significant.

This is just one example of how machining cycles within hyperMILL are making a huge impact on productivity at the JRM Group. Mr Sutton continued: “We have two seats of hyperMILL and we have the flexibility to program parts from home, the office or on the machine. The strategies are excellent and before joining the JRM Group, I had not used CAM for almost 20 years — now I am using hyperCAD-S for designing all the jigs and fixtures we produce and then all the strategies in hyperMILL to reduce my programming and cycle times.

“I can create models, jigs and fixtures by creating the geometry, surfaces and lines in hyperCAD-S. It may be a challenging thought process to design and clamp some of the parts that we have to machine, but with hyperCAD-S, at least we know the drawing and creation of the jigs and fixtures is a straightforward process.”

At the JRM Group, producing jigs and fixtures is a significant role. For example, the company has recently won an order to 3-D print a family of up to 30 motorsport components, which will need finish machining. To undertake this, JRM will 3-D print the parts on its metal printer, but it also has to use hyperCAD-S to design the fixtures for clamping the non-uniform parts for subtractive finish machining — a process that will be undertaken with hyperMILL.

“hyperMILL was new to me when I joined the company, but now I am using strategies such as ‘Z-Level Finishing’, ‘Optimised Roughing’, ‘Drilling Cycles’, ‘Contour Milling’, ‘ISO Machining’, and ‘3-D Free Path Milling’ with complete confidence. The more I use hyperMILL, the more my programming skills are developing.”

With impressive levels of support from Open Mind and an ever-improving level of experience, JRM is maximising the machining strategies within hyperMILL to significantly reduce cycle times, programming times, machine setup times and reduce secondary finishing operations — all while improving tool life and spindle longevity.

High-quality surface finishOne example is the ‘3-D Advanced Milling/Complete Finishing’ cycle. Mr Sutton added: “We frequently machine large aluminium clutch covers that require a high-quality surface finish. The clutch covers incorporate a lot of flat and round surfaces in different directions and to get the optimal surface finish, the tool path needs to move in the right direction with an optimised step-over.

“By applying the ‘Complete Finishing’ cycle, we do not have to pick individual surfaces or create tool paths that need optimising, we can just select the optimal step-over rate — and hyperMILL does the rest. On the clutch covers, we select a small step-over rate of 0.1mm and the machining strategy will automatically determine the tool path directions for the best surface finishes. This may take longer to machine, but we allocate such cycles to lights out machining — wing day.”

‘3-D Optimised Roughing’ is another strategy within hyperMILL that further enhances machining performance. Mr Sutton added: “When we use the ‘3-D Optimised Roughing’ cycle in high-performance mode, we can plunge the tool to a large depth and then remove the material radially. This strategy reduces the stress and forces placed upon the tool and spindle. By plunging to the full depth, we can use the full tool flute length. By setting a metric step-over value, hyperMILL will automatically calculate the percentage of the step-over based on the tool diameter and the volume of material to be removed. This enables us to achieve maximum material removal rates while prolonging tool life.”

Mr Sutton concluded: “It is difficult to quantify the savings that we are achieving with hyperMILL, as our production is predominantly low volume work. However, it is evident that our business is enjoying success and continuous growth and throughout this period, our tool life is improving, as is our spindle usage and throughput.

“Additionally, our programming times are continually falling as our experience with hyperMILL grows, and the ongoing development of the CAM system yields greater efficiencies. Essentially, we are continually increasing our productivity and simultaneously, our programming and machining times and our tooling costs are not escalating in line with output — this is a credit to an extremely efficient CAM system.”