Germany’s

Volkswagen Group (VW) was recently announced as the winner of the prestigious international

Swedish Steel Prize 2025. The prize was awarded for SIBORA, a manufacturing method that opens up for new possibilities when ‘optimising safety components for improved crash performance’.

Eva Petursson, chair of the

Swedish Steel Prize jury and SSAB’s head of research and innovation, said: “With a holistic approach, VW and its partners have developed a press-hardening process to obtain different high-strength and high-ductility properties out of a single steel alloy. Their patented method will provide unique advantages when optimising future car body structures, in terms of weight and performance and with an unshakable focus on safety.”

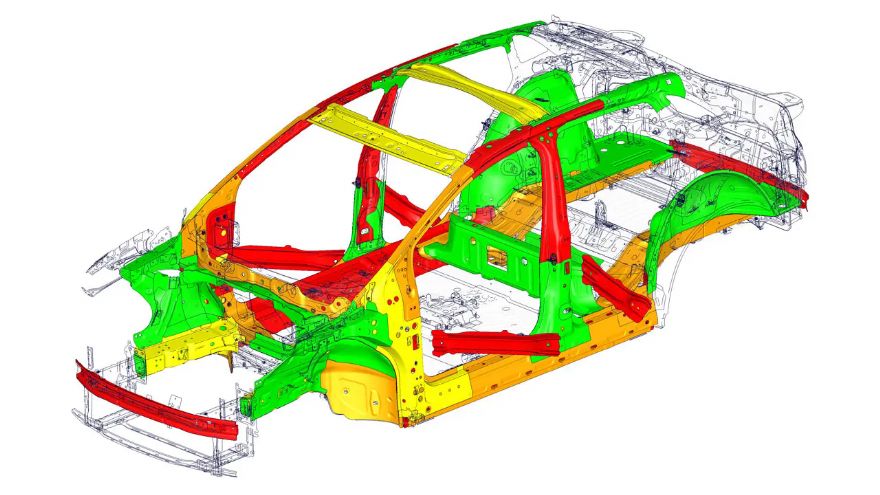

VW, which is the largest car manufacturer in Europe, says it aims to become carbon neutral by 2050, adding that using less material for construction and putting a lighter car on the road is central to reaching this goal. Currently, to combine different properties in one car component — in particular, zones of optimised strength and zones of optimised crash energy absorption — multiple materials must be welded together.

However, with the method developed by Dr Ansgar Hatscher and his team, these specific properties can be achieved using one single sheet of press-hardening steel. The SIBORA alloy concept simultaneously results in high strength and improved ductility and the three-step process can be adjusted to achieve different properties in different areas of the component.

VW says SIBORA will allow stronger, lighter and better car components to be developed faster and in a more targeted manner — with a leaner production process, easier assembly, reduced costs and improved sustainability.

The runners-up for Swedish Steel Prize were: The Greenbrier Companies from the USA; InfiniSpring from Finland; and Loglogic from the UK.