The peace of mind of having a planned preventative machine maintenance scheme is increasingly being realised by customers of every size, says Birmingham-based

Starrag UK, as the market-leading machine tool and systems supplier reflects on a recent flurry of new service deals that complement a host of similar contracts that have been in place for some years with a number of existing users.

In addition to an annual machine service and maintenance plan, Starrag’s ServicePlus programme also covers every eventuality, guaranteeing service response times, inspection and repair, as well as guaranteed uptimes in some cases.

Jim Bradley, Starrag UK’s service manager, said: “You would not expect your car to run reliably without regular servicing and the same is true for a machine tool. The investment in regular maintenance, to ensure the machine is running at optimal levels, is essential and is effectively an investment in a user’s production and, therefore, livelihood.”

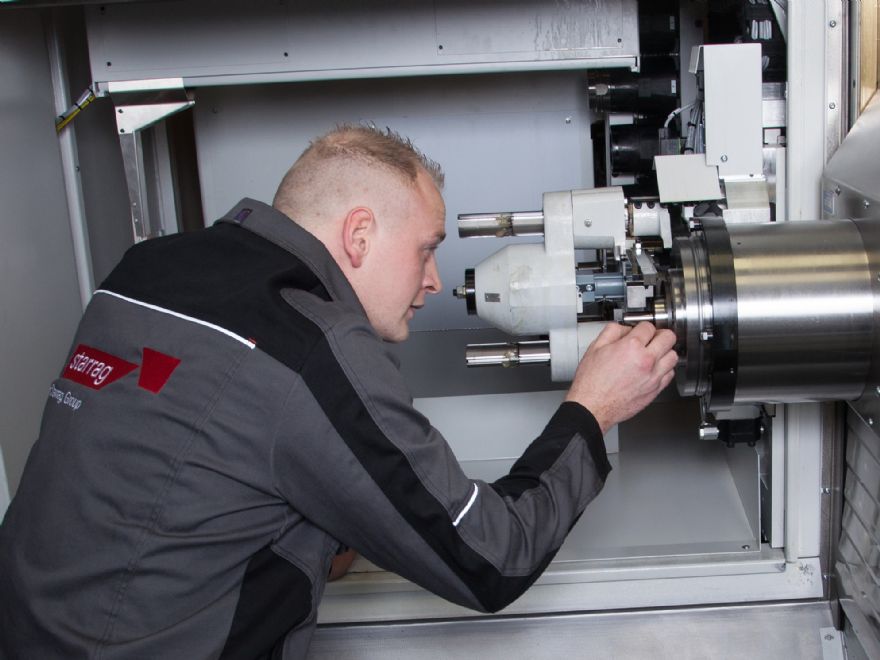

Starrag UK has a team of 20 customer-facing service specialists covering the UK and Eire, including 16 very experienced, highly-trained and skilled ‘mobile’ service engineers who each have an average of 17 to 22 years’ experience of the Starrag machine technologies.

The engineers can deal with every aspect of machine installation and service — and, if they occur, breakdowns — across the numerous machines available from those manufactured and supplied by the Starrag Group product ranges of Berthiez, Bumotec, Dörries, Droop+Rein, Ecospeed, Heckert, Scharmann, SIP and Starrag.

Mr Bradley added: “The company also carries out ad hoc service calls. While more than 70% of our customers are signed up to our planned/preventative maintenance schemes — which can extend for contract periods up to five years — our customer service operation is also geared up to deal with urgent call outs.

“Our response mechanism — which is determined globally by Starrag and measured by key performance indicators — is based on next-day delivery of parts and: a 4hr response after customer call to determine the plan of action — which could simply be support by telephone; and an engineer on site within 48hr. We are constantly being measured by these KPIs and I am pleased to say that we have a 95% record on engineer on-site calls and a 100% record on all machine down cases.”

Starrag’s preventative maintenance schemes are complemented by its online ‘Fingerprint’ machine analysis service which enables remote Starrag service technicians to quickly record machine conditions and, within 24 hours, provide customers with detailed overviews of the degree of wear on their machines’ mechanical assemblies. In addition to helping prevent unplanned wear-related failures — and improve machine availability and productivity — Fingerprint also saves on maintenance costs and enables repairs to be planned.

The service includes: frequency response analyses on all processing axes for monitoring the drive mechanisms — ballscrews, toothed belts — and for identifying resonance points; vibration analysis of the work spindles to determine bearing condition and wear; a circularity test for checking the passage of squares and static friction; measurement of the current consumption of all processing axes; and determining the degree of contamination and wear of the linear measuring systems as well as meter readings and temperature data.

An on-site ’Fingerprint’ is also available by a Starrag service technician, who will carry out further investigations such as additional geometric and thermal measurements.