London-based

CloudNC is to supply precision-manufactured components to the fusion energy industry, thanks to a new agreement with the

UK Atomic Energy Authority (UKAEA).

UKAEA, a UK Government research organisation responsible for the development of fusion energy, has selected CloudNC, a manufacturing technology company, to supply components that support the manufacture of diagnostic windows used in fusion. Diagnostic windows allow observers to view and monitor critical occurrences within complex equipment, such as reactions that take place inside a fusion machine.

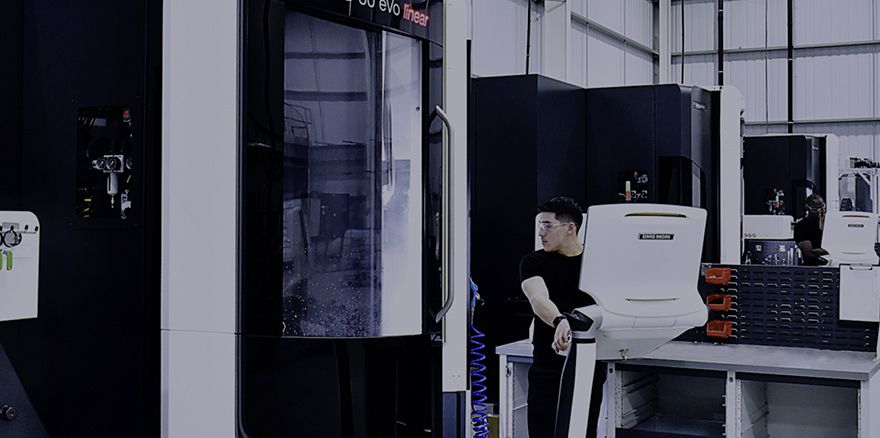

The agreement means that CloudNC will produce components at its factory in Chelmsford, Essex, for UKAEA that are potentially of critical importance to the development of future fusion power plants in the UK and the world. It is the first time that CloudNC has manufactured components for the fusion industry.

Theo Saville, chief executive and founder of CloudNC, said: “Manufacturing components for the fusion energy sector presents unique challenges, as most commercially available materials and techniques cannot withstand close proximity to such fundamental reactions. As a result, the parts must be manufactured to exacting standards, requiring advanced metrology equipment, as well as a meticulous focus on quality — both of which we provide. I look forward to our components making a difference to the next generation of fusion machines, both now and through new supply deals in the future.”

Samuel Nouvellon, project manager at UKAEA for the development and production of the diagnostic windows, said: “These components are critical to the development of new research programmes and fusion power plants, and need to be made to the highest specifications. We selected CloudNC because of their ability to meet those requirements, and are pleased to have found a high-quality manufacturer so close to home.”