Since entering into an agreement with the Taiwanese machine tool manufacturer Axile to be the exclusive UK and Ireland technology partner, the

Engineering Technology Group (ETG), Wellesbourne, has received a significant level of enquiries for the manufacturer’s range of five-axis VMCs, heavy-duty double-column machining centres, and mill/turn machine tools — including the Axile G8 series.

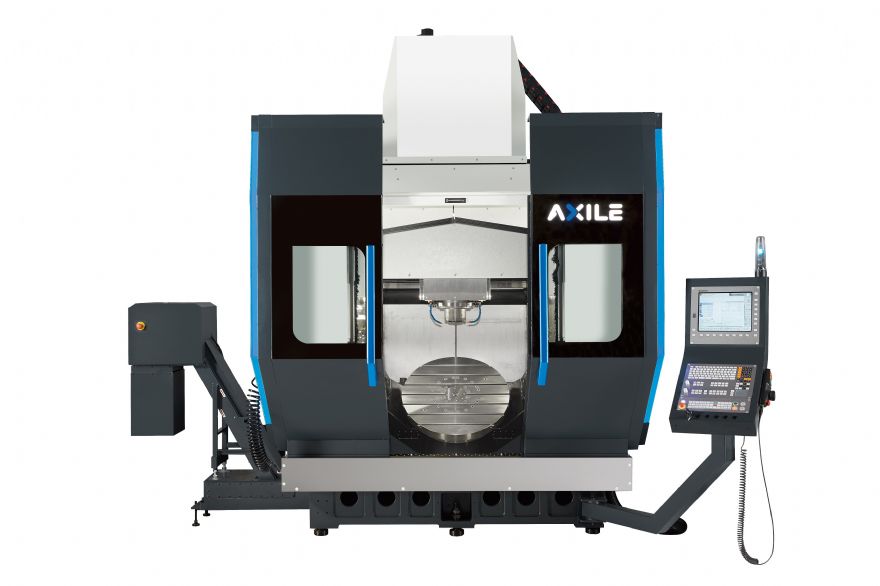

The Axile G8, which is designed for the machining of complex workpieces, offers a maximum loading capacity of up to 1,300kg on a swivelling rotary table. Also in the G8 series is the G8 MT, which offers both milling and turning in one machine, greatly increasing operational flexibility, reducing set-up times and offering the potential to efficiently machine a wider variety of parts in a single setup. Both machine types have a cast base, a substantial U-shaped closed gantry that slides on two symmetrical axes to optimise accessibility and stability, and a chip-disposal unit integrated directly under the table.

The G8 and G8 MT also have direct driven servo motors, ‘double symmetrical and synchronised axes’, linear scales with a 0.1μm resolution, and double roller-type linear guideways. Both also feature an 800mm-diameter table, a work envelope of 670 x 820 x 600mm with a maximum feed rate of 60m/min, a ±120deg swivelling A axis and a 360deg continuous C axis. Meanwhile, the 20,000rev/min spindle is supplied with tools from two tooling carousels that present a 32/64-position tool change; magazine options with up to 120 positions are available.