Warwickshire-based

Ad Hoc Engineering Ltd, an engineering design and precision sub-contract machining specialist based in Warwickshire, with a new DN Solutions’ DNM 4500 vertical machining centre. Supplied by

Mills CNC Ltd, Leamington Spa — the exclusive distributor of DN Solutions (formerly Doosan) and Zayer machine tools in the UK and Ireland — the machine was installed at Ad Hoc’s 1,700ft

2 facility in March 2023 and has been positioned next to three other Doosan machines acquired by the company over the last nine years — a Lynx 220 lathe, a DNM 500 II vertical machining centre, and a Lynx 2100 lathe.

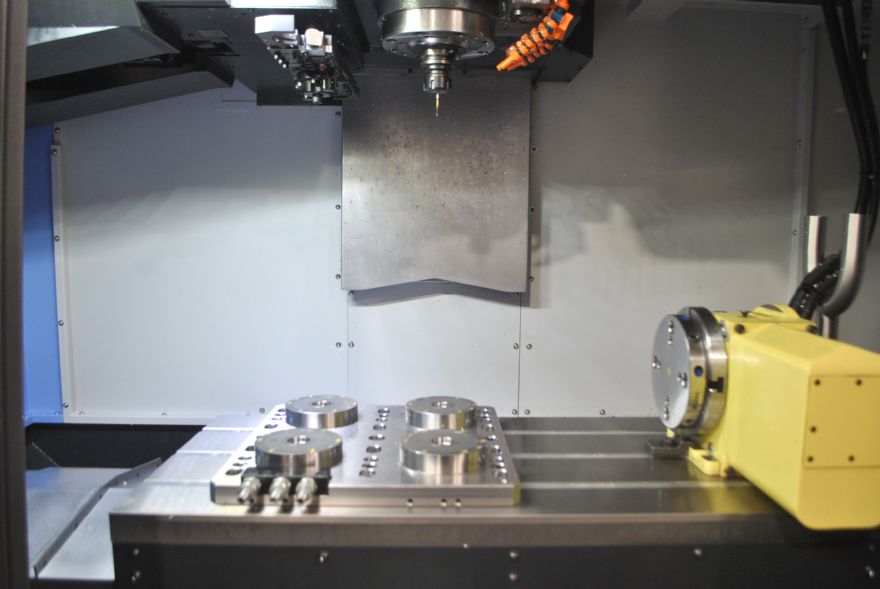

The new DNM 4500 is being used to machine a range of high-precision components and parts for proprietary flow meter and scientific instrumentation products, designed in-house by the company. These parts are typically made from solid aluminium, mild steel and stainless steel bar and billets and are machined in a range of batch sizes, from prototypes and one-offs through to 1,000s-off, using workholding and fixtures that include pallets and tombstones; and while tolerances are tight but not excessively so, the main machining requirements are consistency, repeatability and fast processing speeds.

John Watts Ad Hoc’s owner and director, said: “We provide comprehensive, high-quality machining services to customers and are a vital cog in their process chains. As such, we need to be able to anticipate and respond quickly to their changing production requirements and needed to strengthen our in-house milling capabilities by investing in a reliable, high-performance production-oriented machine.

We drew up a detailed specification checklist for our new investment. As an existing Doosan user, we have a great relationship with Mills CNC and the three Doosan machines we had from them in the past have all performed well. It therefore made sense to contact Mills first; and having discussed our needs and requirements with them and seen a DNM 4500 in action at their showroom, the deal was done.”

The DNM 4500 supplied to Ad Hoc has an 18.5kW 12,000rev/min BT 40 direct-drive spindle, a 30-tool position ATC, a 1,000 x 450mm table with a 600kg maximum load, a Fanuc 0iMP control with a 15in touchscreen iHMI, roller-type LM guideways, 36m/min rapids, and an integrated thermal compensation system. The machine was also fitted with a 20bar though-spindle coolant capability, a Nikken CNC 202 (fourth-axis) rotary table, and an expandable work-holding system from Micro-Loc comprising plates, vices, and clamps.