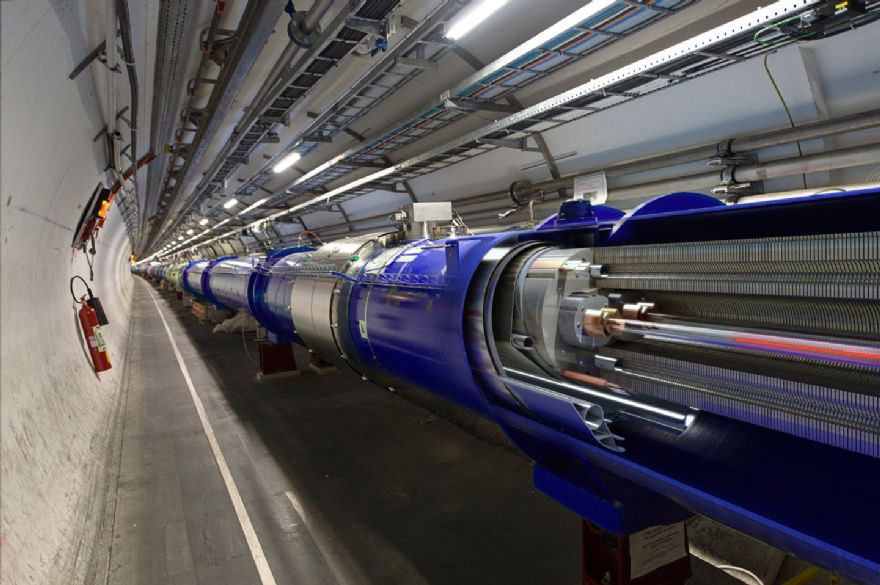

Large Hadron Collider. Photo: Dominguez, Daniel/CERN

Large Hadron Collider. Photo: Dominguez, Daniel/CERNWith 23 member states,

CERN, the European Organisation for Nuclear Research, is the world’s largest research centre for particle physics and its goal is to provide around 12,000 visiting scientists from top universities around the world with the tools to study the fundamental particles of the Universe. It turns out that the tools, built and housed at CERN and needed by the scientists to prove theories about the origins of the Universe, are some of the most-complex machines ever built.

The Large Hadron Collider at CERN is the largest collider in the accelerator complex, and consists of millions of high-tech components installed in a circular tunnel that is 16.7 miles long and situated 330ft beneath the border between France and Switzerland. Getting the equipment up and running was no small task; the total cost of the project was approximately $9 billion.

The experiments CERN conducts are highly complex; during experiments, particles are accelerated to 99.999999% the speed of light and reach extreme temperatures as high as 10 quadrillion °C. The Large Hadron Collider needs to be cooled through cryogenics to temperatures that are colder than outer space. To achieve the organisation’s goals, CERN required a tool that could help minimise unscheduled accelerator downtime while maintaining the safety and convenience of employees and visitors.

CERN has been a

HxGN EAM customer since 1989, and has tracked technical data and maintenance of key pieces of equipment in the accelerator complex since they were manufactured on the shopfloor. At the CERN Control Center, which ensures the accelerators are operating as they should, EAM provides a clear view of the maintenance history to control room operators who use that information to diagnose a malfunction and ensure that corrective maintenance occurs as quickly as possible.

That same level of visibility into maintenance history helps the Cryogenics group optimise when and how much preventative maintenance should be performed in relation to corrective maintenance; this, in conjunction with the replacement parts that are selected, can help CERN achieve the same level of performance from the equipment at a lower cost.

The ultimate goal of CERN is to advance science. The organisation has been tremendously successful at doing this so far, as evidenced by the multiple Nobel laureates who have conducted their research in collaboration with CERN. Much of that has to do with the brilliance of the individuals CERN attracts; however, these individuals must accumulate a large amount of experimental data before they can validate their theories. By maximising the uptime of the equipment and the surrounding infrastructure, the operational support groups help maximise the organisation’s goals.

HxGN EAM is used at CERN to organise and carry out corrective maintenance on pieces of equipment that break down, increase the efficiency and speed of scheduled maintenance and increase safety throughout the organisation.

David Widegren, CERN’s head of engineering information management, said: “HxGN EAM helps CERN manage a wide array of maintenance activities for many types of equipment from the Large Hadron Collider’s magnets to everyday infrastructure such as elevators and fire extinguishers.”

HxGN EAM is used at CERN for the traceability of potentially radioactive equipment, ensuring that all equipment coming out of the accelerator complex is properly measured for radiation and dealt with appropriately. Once an easy-to-use airport kiosk-like interface was introduced, EAM adoption by scientists and technicians skyrocketed.

This provided CERN with the data that was required to comply with regulators and optimise the efficiency of the radiation protection group and the outside contractors that transport equipment to the appropriate locations. The centralisation of information through EAM allows the radiation protection group to increase its efficiency by making scheduled pick ups rather than sporadically visiting each exit point where equipment can leave the accelerator complex.

This helps reduce the cost associated with sub-contractors in this process and gets the equipment back to end users faster, maximising the amount of science that gets done.

HxGN EAM and Infor LN work togetherHxGN EAM and Infor LN impact CERN in countless areas, including both complex and simple processes. LN takes care of supply chain operations and the purchases of all of the infrastructure inputs that allow the CERN community to thrive. This includes much of what is needed within the 700-plus building campus, from the food in the restaurants to the merchandise in the stores for scientists and tourists alike.

There are a number of instances where CERN procures products and takes responsibility for its maintenance, such as with personal safety equipment and car and electronic equipment rentals. In these cases, LN and EAM work together to take care of the full equipment life cycle — from purchase to retirement.

Mr Widegren added: “What we do at CERN is something quite unique, we collide particles at very high energies to recreate the Universe like it was like just a fraction of a second after the Big Bang and by doing so we see particles and phenomena we wouldn’t see otherwise.”

Going forward, CERN expects to expand its strategy to use homogenous and streamlined maintenance processes throughout the organisation for both maintenance management and asset management. There are currently 3 million physical assets managed by HxGN EAM; the goal is to extend the usage to include the whole accelerator complex and a larger portion of CERN’s infrastructure, which could mean doubling both the current amount of work orders and managed assets during the coming three to five years. This is an ambitious yet realistic goal, these numbers already doubled in EAM during the last 60 months.

CERN will also focus on further increasing the integration between Infor LN and HxGN EAM. Centralisation of information through EAM could help reduce costs in everyday activities. For example, monitoring the trends associated with indoor lighting replacement across the organisation could enable centralised purchasing (buying in larger quantities), which would increase its buying power and allow more favourable contracts to be negotiated with suppliers. Given CERN’s size, this type of strategic initiative applied across the organisation could leverage significant benefits.