Designed and engineered by Poland-based

Evatronix, and available in the UK from Market Harborough-based

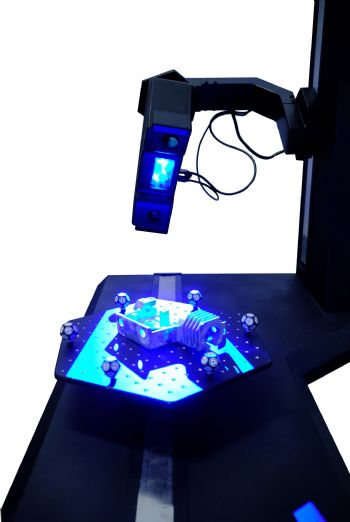

Optimax MII Ltd, the new eviXmatic 2.0 is an automated five-axis 3-D scanning system that enables measuring and quality inspection of objects with minimal operator involvement. A dedicated ‘automation’ module built into the eviXscan 3D Suite scanner software, allows users to easily connect the three-axes device head mechanism with the scanner and allows user-defined scanning scenarios for every object to be scanned with the device.

Scanning scenarios can be composed of several individual scan steps, each of them defines the scanner position with respect to the scanned object and specific scanning parameters to be applied in each scanning position.

After acquiring all the scans in the scenario, the system software performs an automatic merging of the scans and generates an STL file. When combined with the Geomagic Control X software, the system can automatically create a pre-defined quality control report for the scanned object. The API provided provides the ability to trigger the scan scenario with an external signal or device. This can be applied, for example, to a QR code reader that sends the part reference number to the eviXscan 3D Suite software which, after the identification, executes the specific scanning scenario defined for this specific QR code.

The eviXmatic system is conceived for repetitive, fast, precise measuring and quality inspection tasks and as such is a valuable addition to any production line where objects of complex shapes are manufactured and need to be verified.