The Polyline project, which brought together 15 industrial and research partners from Germany to develop a next-generation digitalised production line achieved the first successful implementation of an automated additive manufacturing (AM) production system for polymer parts at scale. At BMW’s Additive Manufacturing Campus, the project partners — including

BMW,

DyeMansion,

EOS, and

Grenzebach — made 3-D printing serial production with high throughput a reality, with the project confirming that an end-to-end automated factory is possible with 3-D printing.

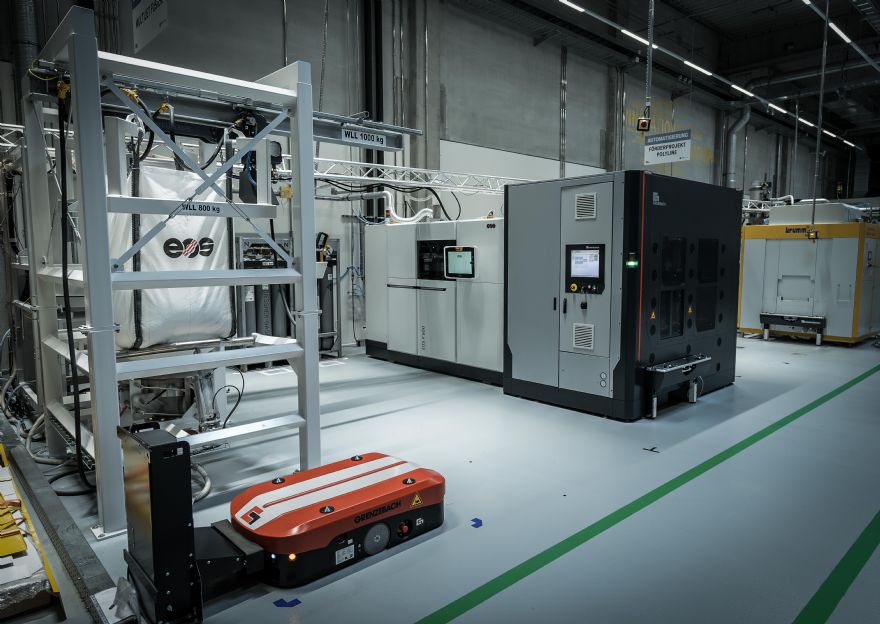

BMW, the premium automotive manufacturer, has given the project a home in its Additive Manufacturing Campus in Munich and has taken over the coordination of the different project partners; EOS — a leading technology provider in industrial 3-D printing of metals and plastics — was responsible for the printing with its EOS P 500, a machine that can be ‘fully automated and fully integrated’.

A specialist in automating industrial processes, Grenzebach contributed its expertise in the networking of manufacturing processes to the project. This includes the Exchange P500/4 solution, which is placed directly in the printer and automatically replaces the exchange frame and cools the build jobs in the buffer stations, as well as the automated transport (via AGV) of the exchange frame to the next stations. Also, the robotic cell with KLT handling and bin-picking robots for the further processing and sorting of components.

Post-processingDyeMansion, which specialises in post-processing solutions for industrial polymer 3-D printing, was responsible for all areas of post-processing, including cleaning, surfacing, and colouring. DyeMansion’s processes are completely traceable, and its Powershot DUAL Performance cleaning/surfacing machine can process batch after batch continuously without the need for an operator to be present.

Blanka Szost-Ouk, BMW Group’s head of additive manufacturing, pre-development, and planning, said: “Current printers are fast, and soon they will be even faster and the cost per part per unit will be cheaper. The Polyline automated process chain fits into the next generation printers and our standard production requirements; and due to standardised interfaces it is a system-agnostic solution— which is crucial for scaling up additive manufacturing at the BMW Group.”

Oliver Elbert, Grenzebach’s head of AM, added: “The target of the Polyline project was to develop a fully automated selective laser sintering production line; and as an automation company, our part was to develop the layout of the line, provide the automation equipment for the transport between the different machines, and create the machine interfaces together for our project partners. The main advantages of automation are to increase the equipment’s productivity, reduce its downtime, and create a safe work environment for the employees.”