A new, horizontal-spindle, five-axis machining centre has been introduced by

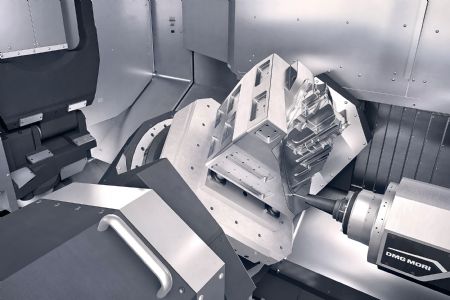

DMG Mori capable of maximising productivity when machining complex workpieces weighing up to one tonne. The robust INH 63 has a working volume of 1,070mm diameter x 1,000mm high and a maximum pallet size of 630 x 630mm. Due to its compact dimensions, it can be integrated easily into automated production systems.

Dies, moulds, battery boxes for electric vehicles and aerospace valve bodies are typical components that might be produced on the machine. Its stable design with a symmetrical structure optimised by FEM and twin ballscrews in all orthogonal axes promote precise, dynamic milling. Magnescale linear encoders result in high positioning accuracy, while reliable cooling of the ballscrews and other sources of heat suppress thermal displacement and changes in the machine structure.

Compared to the previous model, the manufacturer has increased the cutting capacity by 65%. For five-axis machining, the INH 63 swivels the rotary table from +45 to -195deg, direct drive motors delivering speeds of 90rev/min and 30rev/min respectively. The powerMASTER spindle is rated at 12,000rev/min, 808Nm and 85kW (10%), while a version with up to 16,000rev/min or 1,414Nm at 8,000rev/min is optional for heavy-duty cutting. For MASTER spindles, DMG Mori provides a warranty of 36 months with no run-time limit.

The wheel magazine, which has 63 tool positions as standard, can be expanded to six wheels, providing space for 363 tools up to 320mm in diameter x 700mm long and weighing 35kg (optionally 50kg). The high capacity allows long periods of autonomous operation if a large pallet storage solution is integrated.

The INH 63 can be used flexibly in automated production. Either a linear pallet pool or a circular storage system can be supplied, according to the required number of pallet positions and the available production space. Hydraulic clamping pressure is maintained even during automatic pallet change. The machine comes equipped with innovative features that enable energy-efficient operation. For example, the vertical zero-sludgeCOOLANT pro tank increases coolant life, reducing carbon dioxide (CO

2) emissions by up to 7.5 tonnes per year.

Coolant nozzles in the work area having a diameter of 3.8mm do not clog and, with optional AI chip removal to take into account the volume of swarf being generated, a coolant delivery energy reduction of up to 57% is possible. Other energy-saving options include the zeroFOG airborne coolant mist collector, which not only keeps the factory environment clean but also reduces the amount of CO

2 emitted by a further 35%.