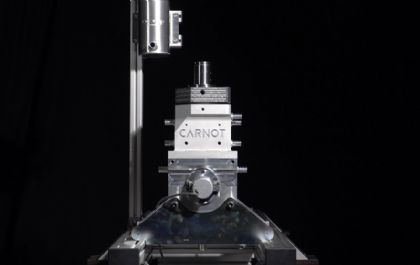

Nadiur Rahman, founder of Carnot

Nadiur Rahman, founder of CarnotA London start-up has signed a new deal with

PTC that will help it tackle the trillion-dollar challenge of decarbonising industry, long-haul transport, and off-grid power.

Carnot, which was formed by Archie Watts-Farmer, Francis Lempp and Nadiur Rahman in 2019, will extend its use of the digital transformation specialist’s CAD design software Creo and its product lifecycle management software Windchill for a further three years.

It comes at an exciting time for the company as it looks to enter an advanced prototype stage for its unique engine technology that removes the cooling system by using advanced materials that can survive ultra-high temperatures.

The ceramics and super alloys used in the design delivers 70% thermal efficiency (compared to the traditional 30% of current engines), zero emissions and, importantly, is fuel agnostic — meaning it can be used alongside combustion fuels, hydrogen, aminos or biofuel.

Carnot is targeting the hardest to abate sectors with its engines first, winning over £5 million of grants to support the development of its technology for use in marine, long-haul road freight and creating primary off grid power in rural locations across the world.

Nadiur Rahman, co-founder of Carnot, said: “These markets are facing an unprecedented shift and rapidly looking to innovation as a tool to achieve ‘net zero’. We believe we have the powertrain solution that can work alongside numerous different fuels to achieve the world’s most efficient engine. Our early development work is drawing attention from all over the globe, as you can see from the funding we have secured in the last 18 months.

“We have won £1 million to turn rice straw biomass into energy in Lombok Island in Indonesia, a £500,000 grant to decarbonise auxiliary power in marine applications and a £2.3 million boost to build an engine demonstrator in conjunction with Carisbrooke Shipping, Brunel University and the Manufacturing Technology Centre — the appetite is there. Our next challenge is to scale up the deployment and start proving our engines in real-world environments, something we are aiming to achieve by the end of 2024.”

Carnot, named after the father of ‘thermodynamics’ Nicolas Léonard Sadi Carnot, has been supported in the development stage by

PLM Central, a PTC partner, which encouraged the three directors to switch to PTC’s Creo cloud-native CAD software to help them with design iterations and to help with scaling up.

This has been a pivotal moment in the start-up’s evolution as the software allowed it to easily handle large models and up to 250 different parts — a previous pain point that had created additional costs and lead times. As the team grew to 10 designers, spread across the UK and Europe, there was also an urgent need to make sure iterations could be made in real time and easily tracked so everyone knew which model they were working on.

Mr Nadiur continued: “I was the lead designer, but still losing track of where we were with changes and iterations. That is why Creo has been such a game-changer and, without doubt, helped us to accelerate the development of the Carnot technology by months, if not years.

“What we did not fully realise we were going to get was world-class data management through Windchill. This basically gave us the capability to standardise data from day one and will be increasingly important as we recruit more designers and open collaboration to suppliers and partners.”

PLM Central, which has provided PTC solutions for more than 28 years, provided an intensive demo to Carnot, even arranging access to the Creators programme that provides flexible finance to start-ups.

Niketh Shetty, director at PLM Central, said: “Creo is such a feature-rich piece of software that it makes perfect sense for disruptors looking to bring new technology to market quickly. Being based in the cloud means information is securely stored and accessed anywhere in the world and, better still, it brings PTC’s product management lifecycle platform into play.”

Elliot Clare, UKi regional director at PTC, concluded: “Windchill has solved a lot of procedures for Carnot, but importantly the firm has only just scratched the surface of what it can do. As the operation scales up, the software will help it deliver change management and bring manufacturing planning into focus for when its engines will be in the marketplace by the close of 2024.”