Stratasys Ltd

Stratasys Ltd, a leading provider of polymer 3-D printing solutions, says that the

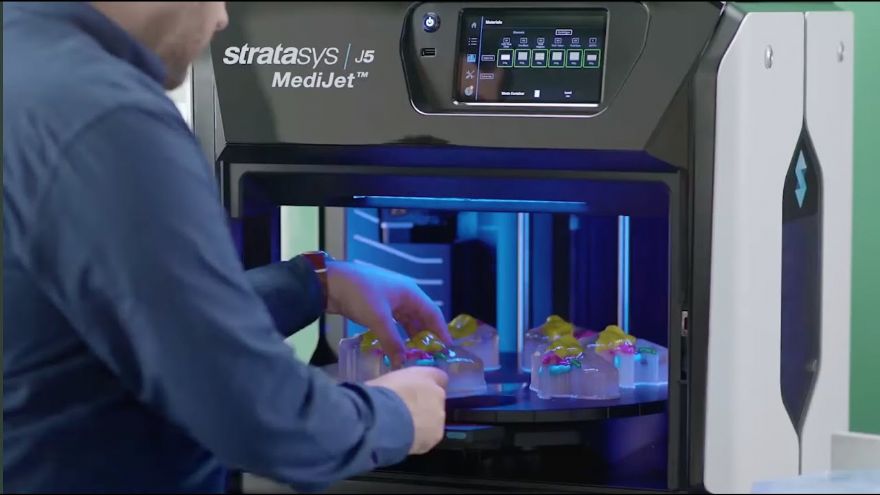

University Hospital Birmingham is delivering improved outcomes for head and neck cancer patients, with the hospital reporting reduced surgery times of up to 3hr using tailored, 3-D printed cutting guides. This success is attributed to the use of a Stratasys J5 MediJet 3-D printer that enables the hospital to create highly accurate, patient-specific cutting guides ahead of operations, transforming the way tumours are removed from head and neck cancer patients.

Previously, guides would have been made by cutting and bending a piece of metal by hand while the patient was on the operating table, resulting in a time-consuming process with a large margin for error. However, with 3-D printing the surgical team can now produce highly accurate devices (with a resolution of within 150µm) using patient scans, thereby helping to support surgical outcomes. These are produced in Biocompatible Clear MED610, a rigid, transparent resin.

Stefan Edmondson, a consultant clinical scientist (reconstructive science) at the hospital, said: “In addition to saving up to 3hr of surgery time, 3-D printing also enables much better surgical planning. Using patient scans, the team can create 3-D visualisations based on the distinct anatomy of each patient, and then leverage 3-D printing technology to produce both anatomical models and personalised surgical cutting guides ahead of the actual operation.

“This capability means we can not only accurately predict the surgery before it is done but also have the tools to ensure that the meticulous pre-surgical planning can be executed with the utmost precision. The surgical team is also much better prepared, and the patient is far more at ease, as we can talk through the process and expected outcomes prior to going into the operating theatre.”

A pioneer in using AM for medical applications, University Hospital Birmingham has long-standing experience with various Stratasys 3-D printers and technologies. The hospital’s multi-material, full colour printer was acquired through Stratasys’ UK-based reseller

Tri-Tech 3D. Launched in 2021, the J5 MediJet gives users the ability to create multi-material, full-colour 3-D printed parts in a single tray.