French company

Aubert & Duval has placed an order with

SMS group in Germany for a hydraulic closed-die forging press for its Pamiers site in Ariège. The contract is at the heart of the company's vision to make Aubert & Duval a leading European metallurgy company, particularly in the fields of aerospace, energy, and defence and to be prepared for the next generation of aircraft.

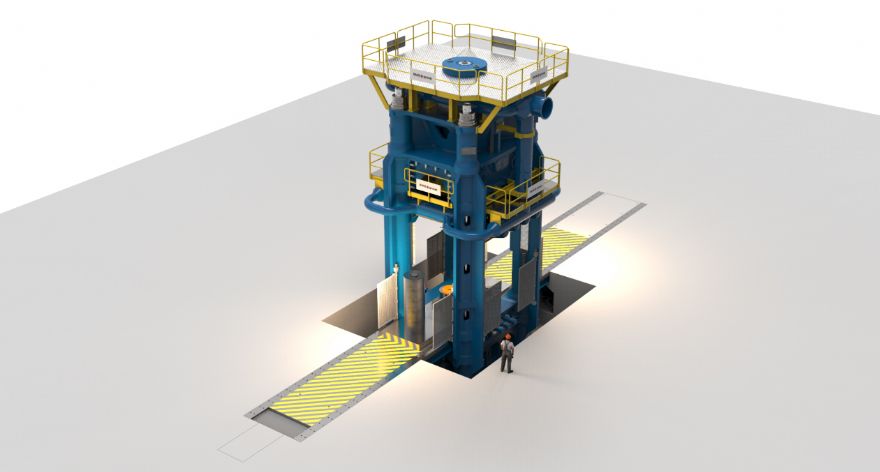

The four-column, hydraulic closed-die forging press to be supplied by SMS has a forging force of 60MN. Going forward, this will enable it to produce intricate forgings, such as turbine disks, shafts and structural parts. The modular structure of the hydraulic press means it can accommodate an isothermal forging module, which Aubert & Duval will use in future to manufacture high-performance components for aircraft and engines based on vacuum powder metallurgy.

The force-transmitting telescopic cylinder is driven by frequency-controlled pumps that can be switched off. This provides for energy-optimised press control with three press force stages (20, 40, and 60MN). What is more, the press is equipped with extensive sensor technology for future digitalisation, and is thus ready for Industry 4.0. It is scheduled to go into operation in 2027 and will replace an older Schloemann closed-die forging press also supplied by SMS, which was built in 1932. Thanks to the new, ‘state of the art’ automated environment, the new press will be better integrated into the existing production infrastructure.

Decarbonisation targetsThe new plant contributes to achieving Aubert & Duval’s decarbonisation targets, as it operates in a far more energy-efficient way than the old press. Not only that, the forgings that the new press can manufacture allow the turbines to be designed more cost-effectively and with a higher level of performance, leading to a significant improvement in the efficiency of the turbines.

Bruno Durand, CEO of Aubert & Duval, said: “This major investment paves the way for Aubert & Duval’s medium- and long-term future. In serving our customers, our primary goal is to modernize and drastically improve our our performance and capability. Yet to make Aubert & Duval the metallurgy leader in Europe, we need to look even further ahead and anticipate what technical developments are to come: This is also the task of this new instrument. We would like to thank shareholders who, by making this investment, demonstrate the trust and ambition they have in the company and its teams.”

Thomas Winterfeldt, SMS group’s executive vice president of forging plants, concluded: “With this new forging technology, Aubert & Duval can process completely new material combinations and thus make a significant contribution to achieving greater drive efficiency for aerospace applications.”