Gears are essential components for transmitting power in everything from industrial machinery to aerospace, construction, automotive and electric vehicles (EVs) as well as a host of other market segments like electric bicycles. Machining gear components demands impeccable precision levels and there are several dedicated machines specially designed for this purpose, such as hobbing machines.

Hobbing machines are commonly used throughout the industry, however, manufacturers often face issues with multiple setups and the application of jigs and fixtures. This is compounded when factors are included such as a shortage of skilled workers and the excessive floorspace required for multiple dedicated machines. These issues can be overcome by the Nakamura-Tome turn/mill centres from the

Engineering Technology Group (ETG).

A multi-tasking machine can change this situation because it performs turning, milling, and gear cutting in a single process. Integrating these processes significantly reduces set-up changes, contributing to more efficient production. Moreover, machining quality remains at the same level as that achieved with dedicated machines – in many cases, it can be improved as multiple set-ups are not required.

Both processes are gear-cutting methods and each has its advantages. Hobbing is suitable for manufacturing high-volume parts and external gears, while skiving is used for producing parts ranging from low- to high-volume. Skiving applies to both outer and inner gears and when machining close to the walls on the end of a gear. Hobbing, skiving and other cutting methods can be conducted on multi-tasking machines and these production centres can produce various types of gears such as spur gears and helical gears.

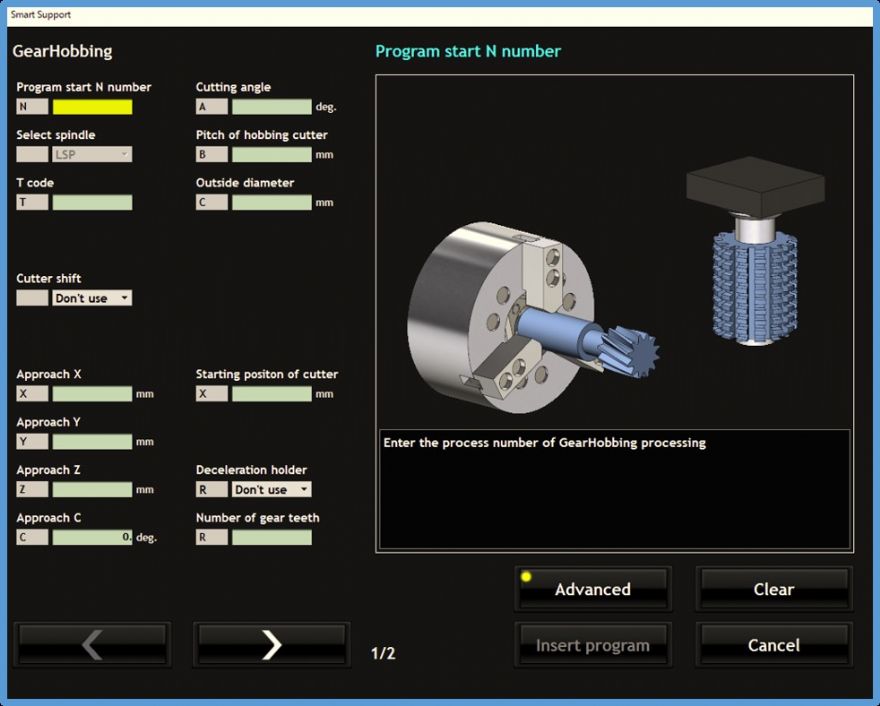

Enhanced programming supportAn investment in a Nakamura machine from ETG, includes the software solution ‘Smart Support’ which simplifies the creation of specialised machining programs that have been developed by Nakamura-Tome through a conversational programming interface.

Recently, the software introduced a gear-hobbing function that now enables users to effortlessly create dedicated programs by inputting variables according to the provided guidelines. To enhance user-friendliness, the software incorporates graphical images to guide operators through the process. Moreover, the intelligent software solution has a hob shift function that is similar to those found in specialist hobbing machines which allows users to shift the contact face of the hob cutter, thereby extending the tool's lifespan significantly.

Nakamura has released a new video showcasing JX-250 and the gear machining capabilities (below). For those interested in reducing their investment in specialist machines annd the costs associated with running multiple machines, it is well worth a watch. It provides a clearer understanding of the software's capabilities in action and includes other cycles that enable users to create specialised programs quickly and easily.