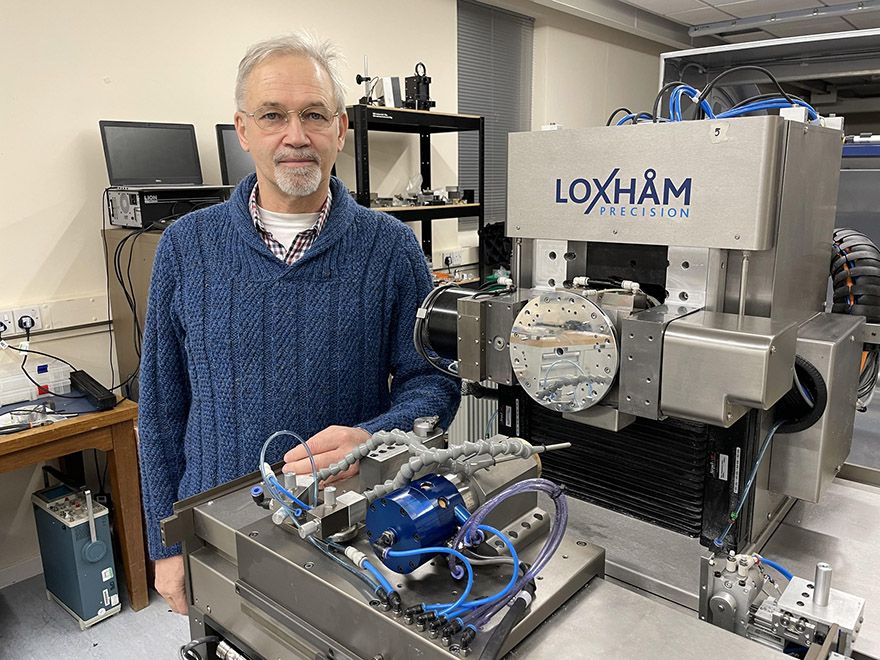

A Loxham u5 machine being built up. Alongside is senior engineer Edwin Helm

A Loxham u5 machine being built up. Alongside is senior engineer Edwin HelmThe world of precision machine tools is a remarkably niche area that is increasingly in demand as certain industry sectors demand ever smaller components with dimensions and tolerances in the ‘micron’ range. Bedfordshire-based

Loxham Precision, a UK manufacturer of ultra-precision machine tools is making waves in this market, but this rapid rise to prominence would not have been possible without partnering with

Open Mind Technologies and its industry-leading hyperMILL CAD/CAM system to develop its machine solutions and market presence.

Industries as diverse as consumer electronics and jewellery, automotive to the semiconductor, aerospace and many more — the world demands smaller parts with tighter dimensions. This is only possible with machine tools capable of delivering micron precision. All machine tool manufacturers want to claim they can achieve it — but only the top echelon actually does. Sitting at the top of this pyramid is Loxham Precision, a company spun out of Cranfield University in 2011.

Located on the campus of the world-renowned university in Bedfordshire, Loxham specialises in the development and manufacture of next-generation ultraprecise machine tools and motion systems. With a product range that includes the BoX free-form grinding machine, the μ6 Micro six-axis Turn/Mill machine, the μ5 Turn/Mill machine and the Aerolox Series 200 of linear motion slides; the niche manufacturer also offers services that range from product development, FEA, dynamics and modal analysis, specialist optic fabrication, ultra-precision fabrication, electrochemical machining, complex device fabrication and specialist bearing manufacturing.

The company’s machine tools can perform everything from diamond turning and micro milling for quantum devices, electro-optics, medical devices, watch components and sensors; providing high flexibility in precision turning and milling suitable for finishing near net complex shape AM substrates, laser targets, electro-optics and air bearing components as well as precision free-form grinding.

As an ex-head of the engineering division at the NPL and also the Cranfield University Precision Institute (CUPE), Loxham Precision CEO, Professor Paul Shore has worked at the very highest levels of academia, industry and cutting-edge research — the perfect background for developing machine tools that break the boundaries of convention. However, when it comes to manufacturing and selling such masterpieces of innovation, Loxham Precision has chosen to work with Open Mind Technologies.

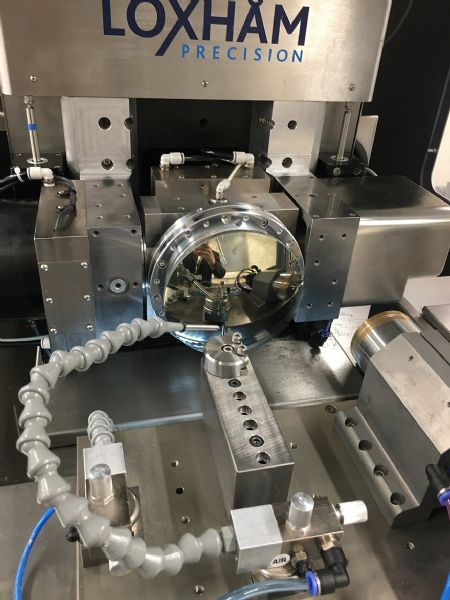

Pictured right: high precision machining with Loxham machines and hyperMILL CAM

Pictured right: high precision machining with Loxham machines and hyperMILL CAMRecalling the start of the relationship, Professor Shore said: “As a machine tool builder, we wanted to work with an industry-leading CAM vendor to not only develop and manufacture many of our machine components but also validate our machine tools. We identified Open Mind as the industry benchmark and entered discussions in 2021. As a small UK machine tool manufacturer, Open Mind provided us with a development licence for hyperMILL their CAD/CAM solution.

“In the three years that we have worked with hyperMILL, we have been bowled over by their level of expertise, innovation and willingness to support us. We were looking for a CAM developer to partner with that has an impeccable reputation for innovation, so we can sell our machine tools with a competent CAD/CAM system that is capable of not only driving our machines but meeting the very diverse demands of our end users.”

Recalling the decision to work with Open Mind, Professor Shore said: “From the very outset, the people and the level of communication was exceptional. Open Mind recognised we are a small UK machine tool builder and they wanted to support us. Additionally, hyperMILL is a CAD/CAM system supported by a team with no boundaries. For example, our machines operate in the ‘nano’ scale, not the ‘micron’ — this deterred some CAM developers from wanting to work with us. Open Mind instantly said that was not a problem. They have not only enabled us to become CAM competent, they have taken charge of certain challenges and made our partnership a seamless and easy process.”

Highlighting an example of this willingness to work with any situation, Professor Shore added: “We do not use a conventional Siemens, Fanuc or Heidenhain CNCs on our machines as we prefer an open architecture system. Open Mind had no problem with this, informing us that whatever CNC system we chose to power our machines they would ‘make it work’.”

Loxham Precision supplies its machines to market segments that were once niche, but are all rapidly expanding to become the norm. As the relationship blossoms, Loxham Precision is offering its machine tools with licences for hyperMILL incorporated to help customers drive their five-axis investments.

Professor Shore concluded: “The relationship with Open Mind is certainly a huge benefit to both parties. Open Mind has supported our CAM competence and given our customers confidence in purchasing machine tools that are driven by an industry-leading CAD/CAM suite. Likewise, our ultra-precise machines are being sold to rapidly ascending market segments and we are opening the doors of these niche areas for Open Mind.”