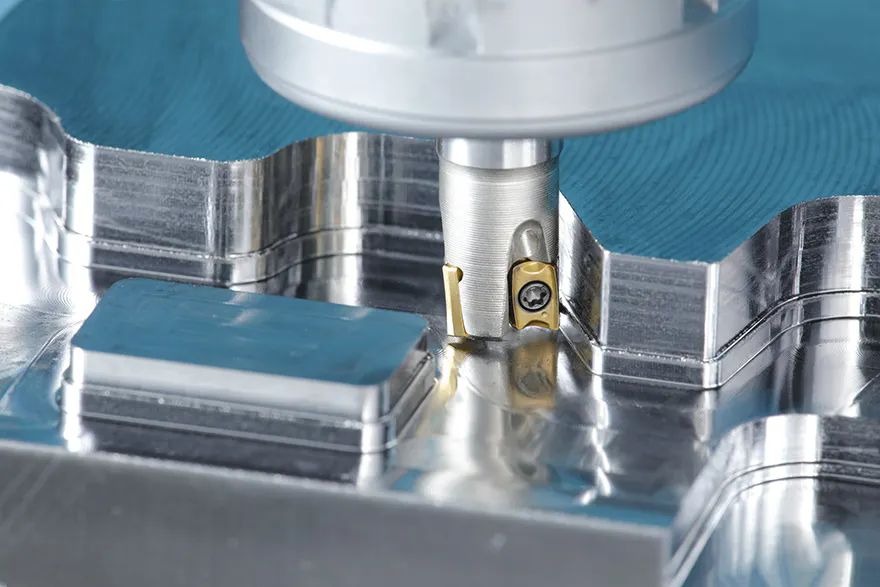

The TaeguTec WIN-MILL high feed line in action

The TaeguTec WIN-MILL high feed line in actionWetherby-based

TaeguTec, a global leader in cutting tool technology, has launched its WIN-MILL series, an innovative range of cutters and CVKT inserts designed specifically for miniature machining applications. This new solution addresses the growing demand for high-performance, cost-effective tooling in precision manufacturing, offering diameter ranges from 6 to 20mm with exceptional versatility and productivity.

The WIN-MILL series represents a major step forward in miniature end mill technology. Unlike traditional solid carbide end mills, the system uses indexable inserts that deliver superior performance. Its design incorporates unique V-shaped, two-corner inserts that enhance stability and precision across a wide range of operations, including shouldering, high-feed milling, ramping, slotting, profiling and cavity machining.

Central to the WIN-MILL series’ success is its V-bottom contact design, which maximises clamping stability between the insert and cutter pocket. This ensures exceptional machining stability during demanding operations such as ramping and high-feed machining while maintaining the precision required for miniature applications. The improved contact geometry offers enhanced rigidity compared to conventional designs, enabling more aggressive machining parameters and longer tool life.

The series also delivers productivity gains through its optimised tooth configuration. While traditional designs typically accommodate one or two inserts per tool, the WIN-MILL series maximises cutting edges. For example, a 10mm dia cutter features three insert pockets compared to the industry standard of two, increasing productivity by up to 50% in certain applications. Larger cutters offer 4, 5 and even 7 insert positions, combined with a larger core diameter for improved rigidity and stability.

Pictured right: the compact CVKT-1-mini inserts

Pictured right: the compact CVKT-1-mini insertsTaeguTec has developed two insert variants to meet specific machining needs. The CVK(H)T 0502PNR series is optimised for shouldering operations, featuring reinforced cutting edges and high rake angles to reduce cutting loads and improve chip evacuation. The CVKT 0502R-HF variant is engineered for high-feed applications, enabling feed rates up to 0.70mm per tooth while maintaining surface quality and dimensional accuracy.

Comprehensive testing confirms the WIN-MILL series’ superior performance across various materials. In trials with SCM4 steel (HB 220–230), the system achieved a 50% productivity improvement over conventional tooling while maintaining excellent surface finish and reducing burr formation. Similar tests on KP4 steel delivered a 30% productivity increase. Inserts are available in TaeguTec’s TT9080, TT8080, TT5525, TT2510 and uncoated UF10 grades, making the WIN-MILL suitable for a wide range of materials.

TaeguTec product manager said: “The WIN-MILL series sets a new benchmark for miniature milling solutions. Its innovative design delivers unmatched stability, productivity and versatility, helping manufacturers achieve higher efficiency and lower costs in precision machining.”

By combining material diversity with broad application capability, the WIN-MILL series offers manufacturers an ideal solution for consolidating tooling inventory. From conventional shouldering and facing to complex profiling, T-slot machining and cavity work, this versatile system enables reduced inventory without sacrificing operational flexibility.