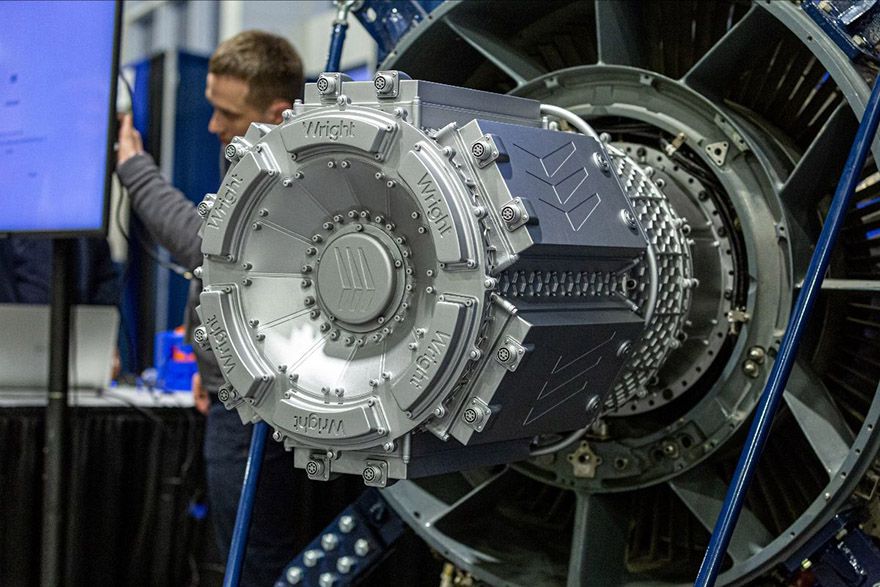

Photo: David Keith PhotographyWright Electric

Photo: David Keith PhotographyWright Electric has announced the launch of the Wright Electric Aircraft Engine Test Cell (WEAETC). Designed to characterise the performance of megawatt-class electric aircraft propulsion systems, WEAETC represents a significant milestone in its journey towards decarbonising the aerospace industry.

Since the company was founded in 2016, Wright Electric has been at the forefront of electric propulsion technology. Collaborating with partners such as NASA, Y Combinator, and The US Department of Energy Advanced Research Projects Agency–Energy (ARPA-E), it has worked tirelessly to develop power-dense electric motors and energy-dense batteries for aerospace and defence applications.

Wright Electric recently achieved a major milestone by testing its industry-leading electric motor to over 1MWh of shaft power. This progress sets the stage for altitude testing at the NASA Electric Aircraft Testbed (NEAT), bringing it closer to its goal of making all single-aisle flights under 800 miles zero emission. At the heart of the testing efforts lies WEAETC, where it validates the thermal and dynamic stability of its 2MWh Electric Propulsion Unit (EPU). As well as being notably quieter than conventional engines, the EPU will revolutionise air travel by paving the way for advancements in electrification technologies.

WEAETC will enable testing on fan-and propeller-based propulsion systems. The testing process will unfold in two key phases. Initially, Wright Electric will conduct ground testing using the 2MWh Wright-1A motor; initial tests will use the LF507-1F fan module and the C-130 propeller. Subsequently, it will embark on the second phase, using its new motor, the WM2500, capable of delivering up to 2.5MWh of power and equipped with an integrated custom drive; this motor has been developed under the ARPA-E ASCEND programme.

Peter Kurowski, propulsion lead at Wright Electric, said: “Using a proven fan module significantly reduces the risk of the test campaign and lets us directly compare the acoustic profile and thermal signature of the electric propulsion unit and its classical turbofan version. The successful ground test campaign will open the doors to a flight test.”

Wright will partner with ARPA-E, Rzeszow University of Technology, REA Space, CFS Aero, Avalon Aerospace, and Executive Jet Support on this campaign.