Castle Donington-based

LK Metrology, the British coordinate measuring machine (CMM) manufacturer, has released the latest version of CAMIO 2024, its measurement, programming, simulation, analysis and reporting software. The new release features upgraded performance in several key areas to enhance safety, increase productivity in the quality control department and shorten the lead-time from component production to completion of inspection.

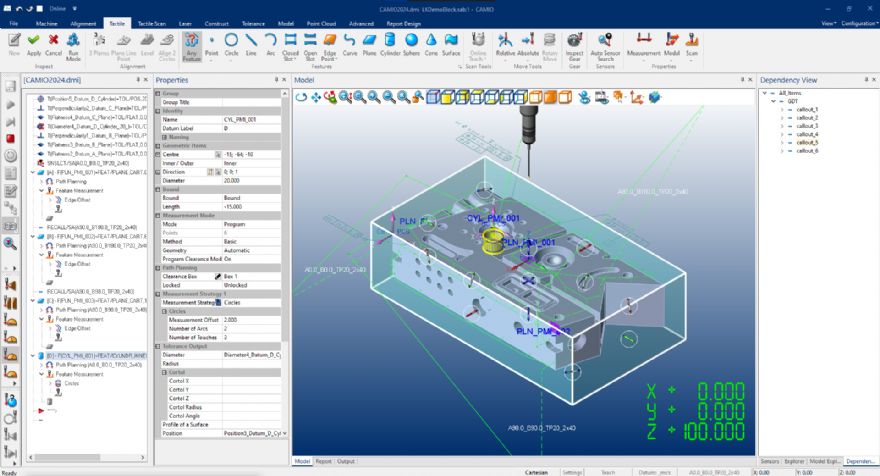

‘Clearance Box’ is a new path planning aid that simplifies and speeds programming by automatically adding clearance moves to prevent the sensor, whether a tactile probe or laser scanner, colliding with the workpiece when moving between measured features or during head repositioning. Working alongside this feature is ‘Auto Sensor Selection’, which raises the efficiency of an inspection program by minimising the total number of probe positions required to measure a part without the programmer having to work out the optimum sequence.

To enhance the user experience, displayed CAD features automatically become semi-transparent to allow easy access to the drag-and-drop tools when configuring the measurement strategy. A further improvement is a new design of manual measurement window incorporating large counter displays to make each contact more noticeable when manually measuring features. This is particularly advantageous when operating CAMIO remotely or at a distance from the PC screen, such as when inspecting large workpieces.

In addition, a new stand-alone utility enables settings from one CMM running CAMIO 2024 to be copied to another. This is useful to users with multiple CMM installations, whether in the same location or spread across different sites, where settings need to be duplicated to harmonise quality processes. Copying CAMIO setting also creates a valuable back-up for data security.

CAMIO 2024 encourages experienced and novice users alike to drive inspection graphically from a CAD model, either online or offline, although ‘teach and learn’ using a CMM handbox is available. An advanced graphical user interface (GUI) makes part alignment, feature inspection and dimensional tolerancing fast and intuitive. The software also supports Metrology Gate, a web-based Industry 4.0 portal enabling production teams to view and analyse quality data and monitor CMM activity from anywhere in the world on an internet-connected device.