When looking to invest in a high-value piece of automation equipment, a key question of any potential purchaser is: what is the payback period? In the UK, the typical expectation is that this will be under two years. However, the value that the right automation solution can deliver to a manufacturing business will last far longer than that. This focus on short-term return is hindering the UK’s productivity as a nation. Our neighbours in the European Union typically expect payback in three to five years, which goes some way towards accounting for their higher levels of both automation and productivity (German workers produces around one-sixth more per hour than their UK co‘nterparts).

Oliver Selby, Fanuc’s head of sales, explained: “Despite our relative reluctance to automate, the UK recently overtook France to become the eighth largest manufacturing nation. However, if we are to continue competing on the global stage, it is imperative that we increase our level of industrial automation – we currently languish in 25th position in the International Federation of Robotics (IFR) global robot league table – not least because of the ongoing labour shortages across all areas of manufacturing. The UK is the only G7 nation to sit outside the top 10 robot adopters; that alone should inspire us to increase our levels of automation in order to drive higher productivity, greater efficiency and increased output.

“To do that, we need to get realistic about return on investment. Focusing on a sub-two year payback can lead to businesses making compromises when developing their manufacturing strategy, and thereafter their capital equipment and automation purchasing strategy, and forces decisions to be made that do not offer long-term value.”

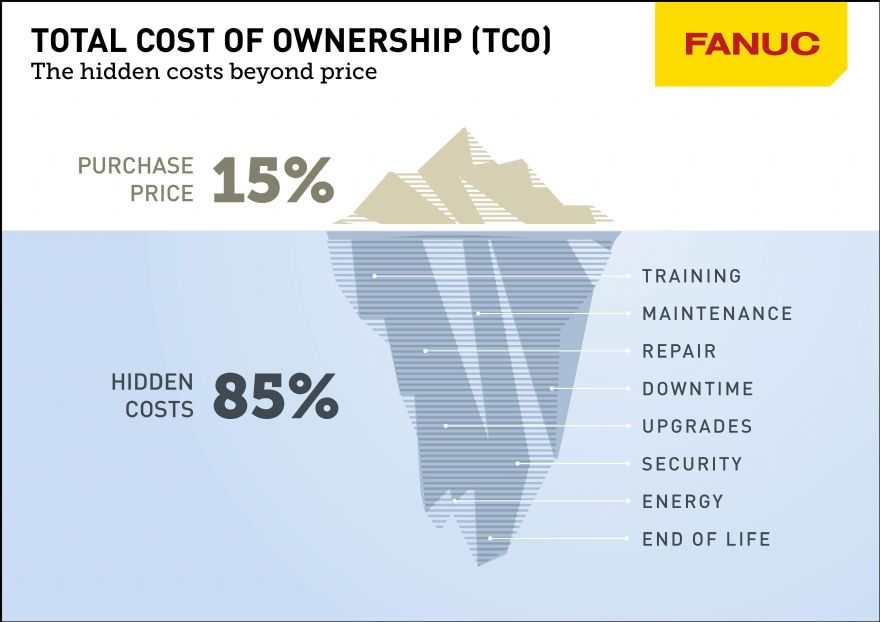

He continued: “By contrast, determining the value of automation using total cost of ownership (TCO) is a far more accurate measure. Any investment in capital or automation equipment should form part of a business’ long-term strategy, and not simply because the purchase price fits into an arbitrary short-term payback period. By calculating the lifetime costs – and more importantly, the lifetime savings – associated with automation, manufacturers can ensure that the sums add up in the long term and not just at the point of purchase, resulting in the right solution for their business both now and in the future.”

Below are the nine factors that make up TCO lifetime costs. Before considering any automation purchase, make sure to talk to your supplier about how their solution can help to control these costs, to ensure you’re getting real value from your investment ...

Purchase price – While much of the focus of any negotiation is concerned with purchase price, it actually only accounts for between 15-25% of the total cost of ownership. Solely focusing on this as the deal-breaker can lead manufacturers to invest in an automation solution which may not be fit for purpose. While Fanuc strives to make its products extremely cost competitive when it comes to the initial purchase price, with as much as 85% of the ‘hidden’ costs of ownership coming via other factors, it is counter intuitive for manufacturers to base their automation investment decision solely on this.

Training – Whether a workforce is used to dealing with smart, connected automated solutions or is unfamiliar with modern robotics, some element of training will be required to ensure that the full value of their equipment can be realised. Fanuc offers an array of upskilling opportunities at its dedicated training facility in Coventry, from basic operating courses to full programming and maintenance courses. Business can future-proof their investments by ensuring that their automation supplier offers full training for the lifetime of the purchase. It is also important to focus on multiple stakeholder levels in the business. When adopting automation, different stakeholders will require different levels of understanding. For example, at shopfloor level a technical level of comprehension will be needed; meanwhile, the C-Suite will need to understand the business case for automation.

Maintenance – Keeping equipment running at optimal levels will ensure it delivers optimum results. Fanuc products are extremely reliable, so much of what the company offers from a servicing perspective falls under preventative maintenance. The company works with its customers to schedule any required maintenance at a time that is least disruptive to their business, maximising equipment uptime.

Repair – The longer a machine is out of action, the greater the financial impact on a business. Fanuc recommends that businesses speak to their supplier to find out what their average engineer response times are. Fanuc UK, for example, is currently sitting at a sub-20hr mean time to repair any faults — less than one business day.

Downtime – Preventing downtime to minimise production losses is essential. As well as ensuring an automation supplier offers preventative maintenance and short repair times, the best way to keep downtime to a minimum is to invest in equipment which has a reputation for reliability. An automation suppliers should be asked for evidence of its products’ mean time between failure (MTBF). For example, the MTBF for the Fanuc CNC range is 25 years, and for its robots it is even longer, at 32 years. Buyers should also find out what services are available to support reduced downtime occurrences, such as augmented reality 24hr support helplines.

Upgrades – With technology evolving at a rapid rate, an automation supplier should be able to equip their purchase with the latest smart software upgrades as they are released. At Fanuc, these include its Zero Downtime (ZDT) programme, which tracks the machines when operational and feeds back performance data to itself and the customer. This helps to predict potential issues ahead of time, keeping downtime to a minimum.

Security – Hand-in-hand with technological advancements comes cybersecurity. Ensuring that equipment, as well the data it handles and produces, are kept secure is a top priority, and something that Fanuc takes extremely seriously. Make sure automation suppliers can clearly explain their cybersecurity measures to help prevent a costly cyber breach.

Energy – No longer a ‘nice to have’, sustainability is now a business imperative from a financial, environmental, social and governance (ESG), and legislative perspective; not to mention essential for winning and retaining key contracts. As well as questioning the energy efficiency of any automation solution in terms of the electricity and gas it consumes, buyers should make sure to also find out its credentials regarding water usage, particularly when it comes to keeping the equipment clean. However, some solutions go even further and actually re-use energy within the process. For example, our all-electric ROBSHOT injection moulding machine has an advanced power regeneration feature that enables intelligent energy recovery, meaning it consumes 10-15% less energy than other all-electric machines.

End of life – Everything has a cost to recycle, so companies also need to factor in a plan for when a product reaches the end of its life. Of course, this will be determined by its expected lifespan. Will it need to be recycled it and a replacement purchased in five years’ time or in 10, 15 or 20 years’ time? At Fanuc, our philosophy is to offer the lowest total cost of ownership for its products with extended lifetime service. This means it will commit to supporting its products for as long as the customer wishes to use them. Fanuc is still supporting robots and machines that are over 30 years old.

Mr Selby concluded: “If UK manufacturing is to retain its place as a global powerhouse, we must increase our levels of automation. This requires a shift in focus by all stakeholders within a business towards purchasing the right equipment first time around and looking at the overall value it can deliver. Prioritising TCO – rather than obsessing over a short payback period – will help to ensure long-term success, supporting a business’ growth strategy to deliver higher productivity and ultimately, higher profitability.”