Krämer+Grebe has 11,000m2 of manufacturing space available to them in Biedenkopf-Wallau, Germany. Photo: Mapal

Krämer+Grebe has 11,000m2 of manufacturing space available to them in Biedenkopf-Wallau, Germany. Photo: MapalTo stay competitive in die and mould making, Germany-based

Krämer+Grebe says it is vital to supplement efficient production with a high degree of process reliability. Tool suppliers are also judged by their application engineering and it is here that

Mapal has earned its cusomer’s trust with its reamers and high-feed milling cutters.

Over the course of the last 100 years, Krämer+Grebe has reinvented itself many times; the company was originally established at the beginning of the 20th century together with a variety of specialised companies around the important ironworks in Germany’s Upper Lahn River Valley. The focus was on classic model assembly in the early years. As time passed, machine engineering became more and more important and the company built foundry machines and prospered by producing meat-processing machines.

In the 1980s, Krämer+Grebe sold its machine engineering department to once again concentrate on its core competency, model assembly. Over time, this gave rise to today’s die and mould making, which is exclusively done for the automotive industry. Customers include large car manufacturers, suppliers and foundries. To also serve their international sites, Krämer+Grebe pursued the path of globalisation and established a presence abroad.

Since Katrin Grebe, the great granddaughter of the company’s founder, took over the helm of the family business in 2000, the progress of change has accelerated — driven by new technical developments and market demands. The company has expanded from a handicraft business into the industrial-scale company it is today. The machinery is all ‘state of the art’ — its 16 machining centres are predominantly from

DMG and

Hermle. On top of this, there is a deep-drilling tool, two lathes, three discharge machines and 3-D printing machines sited in an 11,000m

2 manufacturing space.

The company specialises in finding solutions for complex geometries and particularly stringent requirements for the properties of castings. The process is defined by the requirements for each part. The product portfolio includes models related to the motor and power train. Core boxes, handling devices, gauges and low-pressure moulds are built in Wallau. For lighweight special castings, pressure die cast moulds have been produced at the site for several years. Furthermore, the transition to electric mobility is well underway. Krämer+Grebe generates 20% of its revenue in this area — and this percentage is growing. The focus is on parts for the power train — such as the stator housing for the electric motor — for electric vehicles as well.

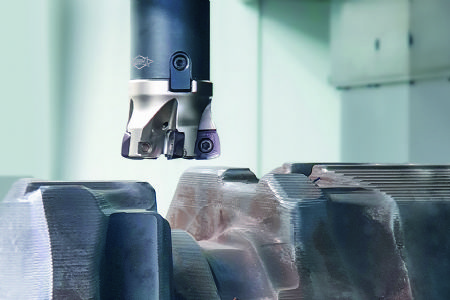

Pictured right: for high-feed cutting, Krämer+Grebe uses the NeoMill-4-HiFeed-90 from Mapal, which beat the competition in terms of performance and process reliability

Pictured right: for high-feed cutting, Krämer+Grebe uses the NeoMill-4-HiFeed-90 from Mapal, which beat the competition in terms of performance and process reliability To remain economical in this competitive environment, manufacturing processes were redesigned and aligned to Industry 4.0 — the workflow is now entirely digitalised. A key role is played by the in-house R&D department, which collaborates with manufacturers to develop components.

Krämer+Grebe has been increasingly focusing its activities on service and no longer wants to merely build tools. Instead, they want to offer clients added value in the form of simulations of tools, wear and tear, series production and cooling. Sebastian Schneider, head of order centre and production, said: “We have also broadened our service and maintenance activities. Our teams are now available to our clients more or less around the clock.”

Mapal only has a relatively small presence among mould makers in Wallau, but has already been able to ensure smoother processes, as confirmed by production. The cooperation between both companies has been ongoing for five years. It began with reamers from the Mapal Multi-Bladed Reamer Centre of Competence. Mapal was the only manufacturer that Krämer+Grebe could find that was able to produce these tools, which are up to 600mm long, at the required high quality and deliver them by the desired deadline. The bores at H7 quality are needed to insert heating cartridges in low-pressure moulds. The tool manufacturer’s application engineers left a lasting impression. They provided user training on site and helped commission the process on the machine, which was running very smoothly from both sides within a very short period.

As part of process optimisation, Krämer+Grebe parted company with some of its former tool suppliers — of which there were many. Dominik Gessner, mechanical manufacturing process optimiser, said: “Today, the price of the tool is no longer the deciding factor. Instead, it comes down to a sensible collaborative partnership and above all application engineering. This is the alpha and omega for us and the knock-out criterion for a supplier. I do not just want a tool, I also want added value that I can apply to my processes.” Gessner asserts that close cooperation with a partner is very important for continuous improvement.

After the good experience with the reamers, Mapal also made his shortlist when it came to improving processes with high-feed milling cutters. Tools were needed with long tool lives that could generate large chip volumes during roughing, thus reducing production times. The milling cutters had to be extremely reliable to allow for multi-machine operation. Mr Schneider explained: “Usually one employee is responsible for two machines in our company — at best, they might be in charge of three.” Through optimisation, staff numbers were reduced from 200 to 130 within five years.

Krämer+Grebe uses the high-feed cutting for pre-roughing before the parts are sent to heat treatment. The mould makers in Wallau took a systematic approach to finding the best tool for the job. They put all the high-feed milling cutters from potential suppliers to the test under realistic conditions. Mapal entered the race with the indexable insert milling cutter NeoMill-4-HiFeed-90, a standard tool which the tool manufacturer offers in the diameter range from 16 to 200mm.

Pictured left: Krämer+Grebe uses a six-bladed NeoMill-4-HiFeed-90 for roughing moulds

Pictured left: Krämer+Grebe uses a six-bladed NeoMill-4-HiFeed-90 for roughing mouldsKrämer+Grebe picked the version with the milling cutter with six indexable inserts for the test. The results were pretty clear: the NeoMill milling cutter achieved the highest material removal rate and longest tool life. The mould makers noted uniform wear on the tool cutting edges without macroscopic flaws. Mr Schneider concluded: “We found out that you can easily operate the machine for 1.5hr unmanned with Mapal. This offers us the big advantage that staff can be deployed at another machine during this time.” So the mould makers found the high-feed milling cutter they were looking for and picked Mapal.

Uwe Rein, business development manager die and mould at Mapal, really appreciates the strategy Krämer+Grebe has chosen. He said: “Companies that make dies and moulds do not have a lot of leeway nowadays to reduce their lead time. However, this is precisely the deciding factor as to whether a company makes money or not. There is only a fine line in between. That is why every opportunity to increase productivity must be grasped.”

Mr Schneider added: “It is also particularly important in individual part manufacturing to use the right strategy with the right parameters and the right tool from the start. We now focus on partners that also offer good application engineering and CAM support. This continues to be our objective and we want to push this forward. We want to work with as few steady partners as possible. Mapal is one of them.”

For the tool manufacturer from Aalen, die and mould is a relatively new segment. They previously concentrated on the most precise and efficient machining of pre-cast parts possible. Now Mapal is getting involved earlier on in the process and, together with mould makers, ensuring that the mould is produced optimally.

Mr Rein concluded: “It is very interesting to be on board from the very start.”