By upgrading its master adaptor from HSK to Walter Capto, Germany-based tool manufacturer

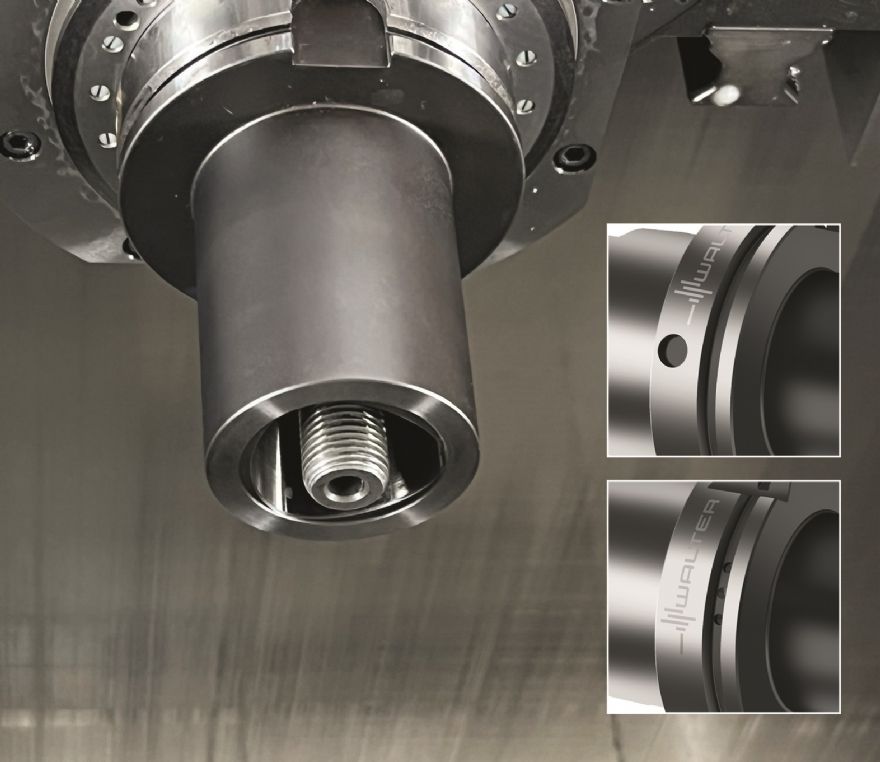

Walter is launching a ‘state of the art’ system interface which features concealed balancing holes, which were previously on the outside of the tool. This balanced construction created at the Walter factory also incorporates a chip hole integrated at the factory.

The user no longer has to drill this hole themselves as the tool provides users with the possibility of digital integration, for example for automated tool management. This is because tool data such as dimensions can be saved by inserting a data chip into the tool that can be accessed when required, such as programming or storage. The Tübingen-based company offers the modular adaptor (HA06-C and HA10-C) from HSK-A to Walter Capto with HSK-A 63 or HSK-A 100 interface in Capto sizes C3–C8.

End users will benefit from the high level of process reliability and precision as the adaptor is very rigid and secondly, from the precise repeat accuracy down to 2µm during tool changes. Furthermore, its incredible versatility makes it suitable for all types of adaptors such as Weldon, ER collets, hydraulic expansion chucks or milling adaptors with arbors for milling and holemaking. This makes the system compatible with all kinds of machines from machining centres through to multi-tasking machines.

Users of data storage devices can open up their entire range of tools with the master adaptor. This is because it can be used with all machines and machining operations and is suitable for universal use with all projection lengths from extensions to reducers.