A CNC-based vision metrology system offers many advantages in the precision measurement and quality control arena. High on the list is the very high precision and accuracy these systems provide, as CNC control ensures consistent, repeatable measurements with sub-micron accuracy, minimising human error. The system is automated and programmable, reducing dependency on operator skill and allowing for batch processing. The use of non-contact measurement, through cameras makes it ideal for fragile or flexible parts, preserving the integrity of the components being inspected.

Vision metrology systems are also much faster than traditional methods, capturing numerous data points quickly and providing real-time feedback, which is particularly beneficial in high-throughput production environments. Additionally, CNC-based vision metrology enables 3-D measurement capabilities, thanks to multi-axis control, which allows the system to measure complex components from different angles. Meanwhile advanced software integration provides robust data analysis and reporting, while features including real-time data collection support statistical process control and ongoing quality improvements.

The flexibility of CNC vision systems is another key strength, as they can measure a wide variety of parts, sizes, and geometries, making them versatile for different industries. Moreover, they require less set-up time, with quick changeovers between different parts and minimal fixturing due to their non-contact nature. Overall, CNC-based vision metrology systems enhance productivity, reduce labour costs, and lower inspection costs over time, making them highly cost-effective in environments where precision and quality are paramount.

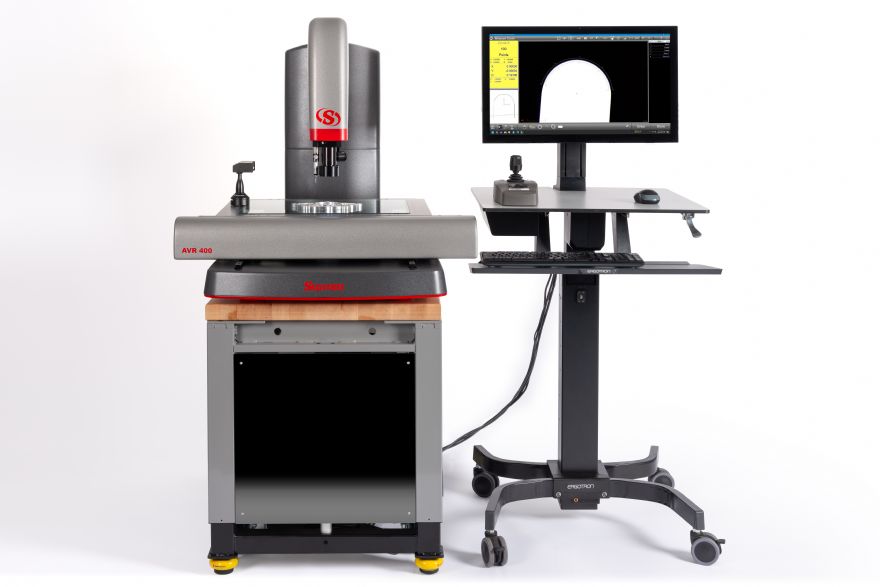

A great example is the AVR 400 from Starrett which is available in the UK from Market Harborough-based

Optimax Imaging Inspection & Measurement Ltd, which features a stage travel of 400 x 300 x 200mm in the X/Y/Z axes, and a stage travel speed capability of up to 120mm/sec. Coupled with the CNC capabilities and a complete line of zoom and telecentric lens options, the AVR400 gives users the option to measure a broad range of part sizes, or larger runs of multiple parts, while simultaneously reducing inspection time — all without having to compromise accuracy.

The AVR 400 features full CNC X/Y/Z positioning or motorised manual positioning using a pendant with joystick and track ball, MetLogix M3 software, video edge detection, pattern recognition capability for automated inspection, colour digital video camera, Touch probe compatible for optional multi-sensory capability, LED substage and ring light illumination.