From concept through design and production with VISI

From concept through design and production with VISIAs one of the world’s leading manufacturers of model railways,

PECO is a forward-looking family business that started trading back in 1946. Initially concentrating its manufacturing skills on the production of trackwork for model railway enthusiasts, the company has grown rapidly. To support its expansion, the Devon-based company relies on VISI CAD/CAM/CAE software from

Hexagon in its design and manufacturing facility.

Located on the idyllic South Devon coast, PECO is a company that has expanded from its humble beginnings of manufacturing individual components to producing HO/OO ready-made track and then on to all things ‘model railway’. This includes ‘Pecorama’ one of Devon’s leading tourist attractions with a model railway exhibition and model shop, a ride-on miniature steam railway, a gallery and award-winning gardens, and industry-leading model railway publications. As a company with a ‘fan base’ as well as a customer base, PECO is a world-renowned brand in the model rail industry. From the foundations that stem from manufacturing a simple coupling, PECO now runs a facility that makes over 3,000 product lines.

Simon Cockerham, PECO toolroom manager, said: “We make everything that is part of the hobby building model railway industry. We have been in business since the 1940s and started as a company making very small couplings that hook two pieces of rolling stock together. It has expanded from there to a business that makes everything from concepts to the final product.”

Pictured right: PECO’s Simon Cockerham with a Hexagon engineer discussing press tooling that has been developed with VISI

Pictured right: PECO’s Simon Cockerham with a Hexagon engineer discussing press tooling that has been developed with VISIWith a manufacturing site that hosts ‘state of the art’ technology, PECO relies on VISI CAD/CAM/CAE software for its workflows. Mr Cockerham continued: “We use VISI throughout our manufacturing facility, from concept through to the final press or mould tool being created. We have numerous licences of VISI throughout our many departments and we also use VISI to generate laser-cut wooden kits for customers with textures upon them. It is also used to create the instructions that will guide enthusiasts and users on how to assemble the equipment.

“VISI has always been very good for our business as it focuses on just what you need to do the job. Some other software packages that we had before VISI had caused issues due to the high tolerancing of our components and the very deep nature of the machining processes that we have to undertake to achieve the geometries that we require in our press and mould tools.”

The complete packageAs one of the world’s leading PC-based CAD/CAE/CAM software solutions, VISI incorporates modules such as ‘Modelling’, ‘Analysis’, ‘Mould Design’, ‘Flow’, ‘Electrode Design’, ‘Die Tool Design’,

‘2.5-, 3- and 5-axis Toolpaths’, ‘Blanks and Reverse’. This provides PECO with the facility to create solid models, design, analyse, validate, and prepare mould tool geometries, and perform pre- and post-production analyses of plastic parts. With dedicated modules for creating electrodes, designing dedicated progressive die design and press tools, comprehensive machining strategies and even reverse engineering of editable solid models from scanned data — VISI provides the complete package for the company.

Mr Cockerham added: “One of the key reasons that we have VISI in our environment, and that we have been customers for almost 17 years, is because it is very reliable and comprehensive. We have an intimate knowledge of the VISI environment and systems throughout our experienced generations of designers and toolmakers who are here. This means we have the experience to support more junior members of the team here — but even we need assistance now and again because every engineer looks at things differently from time to time.

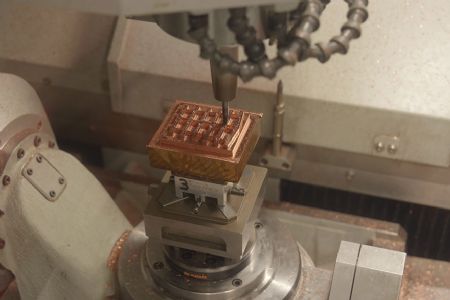

Pictured left: machining electrodes designed and programmed with VISI

Pictured left: machining electrodes designed and programmed with VISI“Another key reason why we use VISI is due to the complexity of our products. We need jobs to be correct first time. We also use very expensive machine tools from Röders, Sodick, and Hurco, as well as high-end peripheral equipment and cutting tools. VISI has always kept us safe throughout the entire process of generating these tools.”

The holistic Hexagon mould and die workflow removes blockers so the team can try new ideas. Mr Cockerham explained: “We use VISI throughout most of our departments, especially within the wider ‘innovations department’. This means we use VISI for everything from design to producing wooden laser-cut kits for the factory to producing custom machinery for our production facilities. We also use VISI for all of our press and mould tooling too. The benefits of having VISI in the workplace are the integration between plot view, CAD/CAM, and the ability to create surface translations for mould flow analysis and laser ablation files. It streamlines integration between departments.”

Many other features the business needs are all connected within a single environment, which makes PECO’s training and application of VISI a lot easier for everyone concerned. Over the 17 years, PECO has standardised its workflows on Hexagon’s mould and die software and positively impacted its business.

Mr Cockerham concluded: “We know we have saved a lot of time and money with VISI. The savings are down to the software having all of the components and modules we require to take our products from concept through to production and then on to export markets worldwide — all from under one roof.”