Kalbarri SkywalkKanyana Engineering

Kalbarri SkywalkKanyana Engineering has followed a policy of providing unique sheet metal services at its Greenfields, Western Australia manufacturing facility since its formation in 1997. Graham Dawe, Kanyana Engineering managing director, said: “We started this process with a 100-tonne press capable of bending 6mm material when our competitors could only bend 3mm material.”

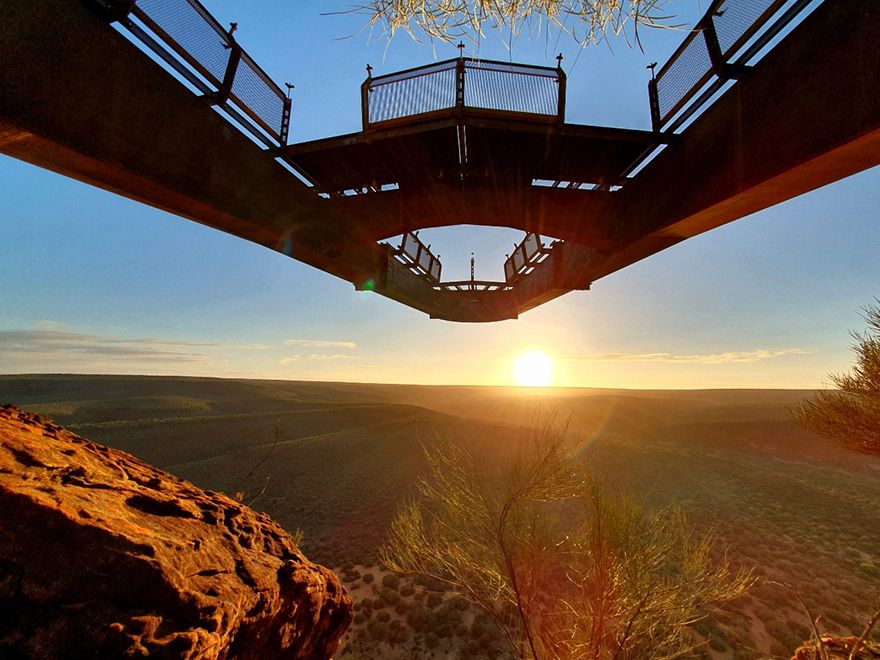

This policy is continuing and now the company has progressed from high-tolerance plasma cutting to fibre laser cutting with a 15kW 1.5 x 3m Bystronic Bystar and the first Bystronic 20kW Penta laser with 2.5 x 6m bed in Western Australia. This machine can cut 50mm mild steel, stainless steel and aluminium, giving the company the largest job shop capacity in the region. The capabilities of the company make it popular for supplying civil, mining, industrial, construction and creative arts projects. The variety is huge and includes balustrades for the Kalbarri Skywalk which soars 100m above the Murchison River Gorge and mining refuge chambers which are designed to protect miners in an emergency.

As part of its pursuit of excellence, Mr Dawe understood that software and the integration of the company’s systems was crucial to his plan. “I had experience from a previous computer business and wanted a fully integrated CAD/CAM and ERP system. With

Lantek, this was all possible and we went for the full suite of Lantek Expert, Flex 3D and Integra straight away. We can take DXF files and 3-D models directly from the customer and use the system to nest parts, program the lasers and calculate a consistent and accurate price for the job, irrespective of who creates the quotation, always offering our best price in a matter of a few minutes.”

Maintaining traceabilityStock material is stored within the system as are remnants from previous jobs so the company knows what is available, what has been earmarked for a job, what needs to be ordered and can trace the material down to the individual sheet used by its tracking number to produce material certificates for the customer. “We can even switch materials, should the sheet we have allocated be under five tonnes of material, picking another of the same specification from the top of the pile and substituting its tracking number to maintain traceability.”

Once a quotation becomes an order, all the details and history of the job are released to the workshop ready for manufacture. Lantek’s MES software keeps control of where parts are in the shop, the time taken for each operation and any lost or damaged parts which need to be remanufactured. The live information is collected via workshop PCs and iPads on the laser machines, the press brakes and in the six fabrication bays, where the operators log in to record and validate what is happening and the state of each part running through the factory, even sub-contracted operations and bought in items are tracked.

Mr Dawe added: “We have put in two extra processes, quality control and pack and dispatch. These are a final check, allowing us to find and remedy any faults, control the status of the customer, for example any credit limits, prepare delivery documentation and material certificates, create the invoice, and finally share the information with our Xero accounting software.”

Lantek’s Integra sales module helps Kanyana see where its orders are coming from, showing sales by staff member or by customer enabling it to analyse which quotations are working best. It also uses information about capacity in the workshop to provide realistic delivery times and looks through material stores to find how much extra material may need to be ordered.

“We aim for a three-day lead time if possible. We run a 1.5-day shift system which is 12-14hr per day, so we can increase this to double shift if we need to create more capacity. With our exact knowledge of production capacity in the factory and automation on the lasers we get much higher beam-on times than most manufacturers can achieve.

“Similarly, with Lantek MES Manager we can always answer the customer’s questions about where their part is just by looking on the system, keeping them in the loop for realistic and accurate delivery dates even though we have thousands of parts going through the workshop at any one time.”

Kanyana installed the Lantek software in 2019 during the Covid-19 pandemic so all the training and installation took place online. Mr Dawe said: “Having an IT background certainly helped as we knew what to expect. Now that we have had the system for a few years we really get the full benefit and, if Lantek tells us that a job will take five days, we know that this is accurate as are the costs involved.”

He concluded: “This means that we can alter our quoting style where necessary to compete for valuable or prestigious projects. Overall, the integration and accuracy of the system, which has been designed for sheet metal applications, is the key to our success, enabling us to be highly responsive and competitive, achieving much more with considerably fewer people than our competitors.”