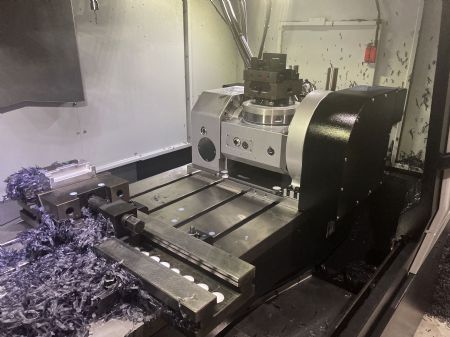

The new DNM 5700 vertical machining centre on the shopfloor at Custom Metalworks

The new DNM 5700 vertical machining centre on the shopfloor at Custom MetalworksLancashire-based Custom Metalworks Ltd, a precision-engineering specialist established in 2023, which provides high-precision CNC machining, customised fabrication and welding, as well as a design for manufacture (DfM) consultancy, has recently invested in a new DN Solutions’ (fourth-generation) DNM 5700 vertical machining centre, from

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland.

The new machine, installed at the company’s machine shop in Ormskirk in June 2024, is powerful, fast and accurate. Furthermore, it is equipped with the latest advanced Fanuc

i Plus control with a 15in touchscreen iHMI, and features an 18.5kW 12,000rev/min directly-coupled 117.8N-m high-torque spindle, a 1,050 x 570mm work table with 1,000kg maximum table load, and a 30-tool position automatic tool changer (ATC).

The machine, supplied to Custom Metalworks as part of an investment package, was delivered alongside a Detron GFA-200EH five-axis rotary table, Renishaw tool and table probing systems, and a Filtermist extraction unit. Since being installed, the DNM 5700 has been put through its paces machining a range of performance-critical plastic components for a leading manufacturer of patient positioning products and equipment including support frames, sets, extensions, systems and attachments, designed for a range of surgical procedures where the patient lies prone on an operating table.

Custom Metalworks machines parts and sub-assemblies for this customer’s best-selling spine frame systems which are versatile, cost-effective table-top platforms, positioned underneath the patient, that can be easily fitted to any standard operating table, and that enables patients to be safely and securely positioned/re-positioned during spinal operations and procedures.

Spine frames are fully radiolucent, and feature spine, hip and chest supports that can be adjusted to accommodate different patients’ height, weight and body types. These supports, made from Nylon 6, are fixed to each frame system’s parallel rails by clip locks that have a quick-release function.

Jack Eckersley, Custom Metalworks’ owner and managing director, who is also an apprentice trained, time-served engineer, said: “Nylon 6 is a durable and reliable engineering plastic with high mechanical resistance that exhibits good machinability characteristics and sliding properties. The Nylon parts we machine are accurate and require a good surface finish, but geometric tolerances are not that exacting. We machine the parts using coolant, as opposed to adopting ‘dry’ machining methods, in order to control heat build-up, protect tool life and optimise chip evacuation from the cutting zone. The key manufacturing issues for us machining these parts concern component repeatabilities, security of supply, lead time fulfilment and cost.”

Varying batch sizesCustom Metalworks machines and supplies batches of supports, which comprise brackets, clips and modular sides, to the customer. Batch sizes vary depending on the support itself and the customer’s order requirements, but can be up to 200-off per month for certain products, and less for others. Part cycle times are typically around 30min allowing Mr Eckersley to focus on other activities such as fabrication and welding, design consultancy projects or administration, while the machine is running. In addition to Nylon 6, Custom Metalworks has also machined stainless steel and aluminium components and fixtures on the new machine.

Mr Eckersley started his engineering career at a leading design and manufacturer of innovative, high-quality products and solutions for the glass container manufacturing industry. Having completed his four-year apprenticeship at the company, plus an additional period of time on the shopfloor working as a manufacturing engineer, Jack made the decision to leave and start up his own precision engineering sub-contract business – providing specialist high-quality CNC machining and fabrication and welding services to customers.

He continued: “It is something I always wanted to do. I was confident that my toolmaking background combined with experience in CAD/CAM, CNC milling, inspection, reverse engineering and design for manufacturing would stand me in good stead and ensure that the new venture would be a success.”

At around the same time as setting up the new company, Mr Eckersley was presented with an opportunity that ultimately shaped the direction of travel for his fledging business. He explained: “I was introduced to a local medical equipment company that specialised in the design and manufacture of innovative patient positioning products. The company had recently decided to bring its manufacturing operations in-house and had already invested in a number of CNC machine tools, including a simultaneous five-axis machining centre, but needed help in setting it all up, and in developing secure and efficient programs and processes to machine components for its product ranges.”

Monumental decisionHe took the decision, monumental as it transpired, to join the company, working during the day in its machine shop while focusing on his new business venture in the evenings and at weekends. This arrangement enabled Mr Eckersley to build a good working relationship with the customer, acquire a thorough understanding of its product ranges and, seeing as he had developed many of them, understand its manufacturing methods and processes inside out.

However, after a few months, instead of ‘burning the candle at both ends’, trying to run the customer’s machine shop while, at the same time, getting his own business up and running – a mutually beneficial decision was made to transfer all of the customer’s machining operations over to Custom Metalworks.

Mr Eckersley said: “We, in effect, became the customer’s de facto machine shop. But, to cope with this new influx of work, we needed to increase our machining capacity and capabilities quickly. From a cost and capability perspective, I made the decision not to replicate what was already in place at the customer’s machine shop, preferring, instead, to purchase a smaller, high-performance and more flexible three-axis machining centre with large working envelope and a fifth-axis rotary table with hydraulic clamping capabilities for 3+2 and 4+1 machining of specific parts and fixtures.”

Mr Eckersley did his homework and narrowed down his search of potential machine tool suppliers. Having already had experience of Doosan machines and Mills CNC from his time at a glass container manufacturing company, he approached the machine tool supplier to find out more about the company’s three-axis milling ranges, and was introduced to the popular and proven DNM series. This ultimately culminated in a visit to Mills CNC’s stand at

MACH 2024 where he saw the new fourth-generation DN Solutions’ DNM 5700 in action.

Mr Eckersley said: “I was looking for a machine that delivered fast processing speeds, high accuracies and good surface finishes, and that would enable us to machine large and/or smaller multiple parts in a single setup. The DNM 5700, with its advanced spindle technology, rigid and thermally-stable build, fast rapids and large working envelope, seemed to offer the perfect solution. Having talked to Mills CNC, I placed the order there and then at

MACH 2024. Since being installed in June 2024, the DNM 5700, following on-site training, has been working flat out.”

Custom Metalworks offers something unique to the market and its customers - high-quality machining, customised fabrication and welding services, as well as a design for manufacturing consultancy. The investment in the DNM 5700 has enhanced the company’s machining capacity, capabilities and flexibility, and although Mr Eckersley is working long hours, the DNM 5700 is coping well with the demands placed upon it.

With one eye on the future, Custom Metalworks is now looking at the potential of streamlining its machining operations by investing in a robot handling system to further increase productivity and improve process efficiencies.