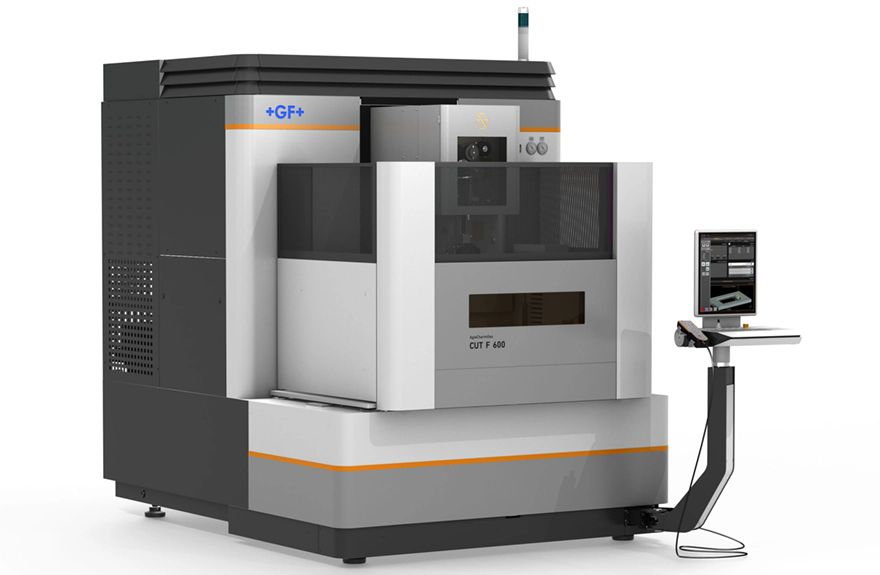

The CUT F 600

The CUT F 600Coventry-based

GF Machining Solutions Ltd (GFMS), the EDM, milling, laser and additive manufacturing (AM) machine tool manufacturer and supplier of advanced automation, work-holding and tooling systems, has unveiled a new thermally stable wire EDM machine.

The CUT F 600 is a thermally stable wire EDM machine that automatically identifies and adapts wire speed during the cutting performance leading to improved productivity and process reliability and is considered ideal for component and mould tool manufacturers as it is designed to balance precision with productivity for accurate machining and high surface finishes.

Designed for ease-of-use and flexibility, the machine features the innovative Uniqua control, ISPS (Intelligent Spark Protection System) and iWire intelligent functions and the much vaunted radio frequency identification (RFID) Smart Wire system, along with design improvements for thermal stabilisation, vibration control and highly-precise machine movements.

The iWire function automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process. According to the company, this capability eliminates wire breakage while reducing overall wire consumption per job. The iWire function works in tandem with the company’s ISPS, both of which are accessed via the Uniqua control.

Additionally, iWire not only recognises exactly where the sparks are occurring during the WEDM process, but also measures and identifies the position of each spark along the length of the wire. Knowing the exact location of a spark enables iWire to automatically adapt the wire spool speed accordingly.

For precise machine movements, vibration control and overall process stability, CUT F series machines provide the work tank and dielectric fluid to cool the machine’s axis optical encoders. A further design innovation is the incorporation of higher accuracy machine ballscrews that improve both positioning accuracy and smooth operation.

The CUT F 600’s Uniqua’s human-machine interface (HMI) features a 19in vertical touchscreen, full keyboard and mouse. It supports legacy file types from various EDM manufacturers, and with offline and at-the-machine programming, plus ISO-based functionality and object-oriented programming, provides a powerful graphic tool with integrated CAM that is compatible with all major CAD/CAM programs.