Southampton-based

Rigging Projects, a specialist in the design and manufacture of marine hardware and sailing systems, is tapping into the advantages of Vericut CNC simulation, verification, optimisation and post-processing software to drive home the gains available from a sizable investment in its first five-axis machining centre. Using Vericut, the company has complete peace-of-mind in the single set-up machining of complex parts with curved freeform surfaces — confident there will be no collisions and no expensive repairs.

Tobias Hochreutener founded Rigging Projects in 2014 based on his vision of a rigging consultancy business that put smart ideas, trustworthy services and high-quality products at its core. From humble beginnings in his tiny home office, the company now has over 30 employees, four

DAME Design Award Special Mentions and a high-technology manufacturing facility in Hampshire.

Mostly serving designers and builders of superyachts and race yachts, Rigging Projects produces an array of deck hardware that handles lines or sails. Both standard and custom solutions are available, with the company offering an end-to-end design and consultancy service for client projects, whether new build or retrofit. Component manufacturing takes place at the company’s ‘state of the art’ machine shop in Totton, Southampton, which should be ISO90001 accredited by later this year.

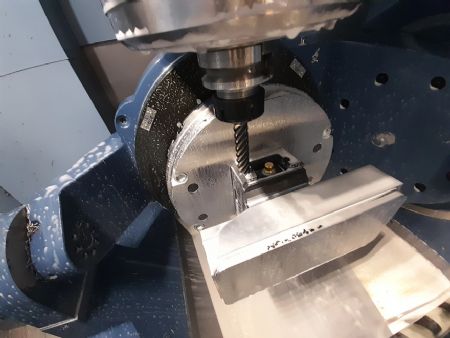

The impressive new centrepiece of the machine shop is a Matsuura MAM72-52V, a colossal high-speed five-axis vertical machining centre described as a ‘factory in one machine’ for variable-part/variable-volume production and extended unmanned operation. Standard features include 130 tools on a 330-tool magazine base, a tower pallet system for extended lights-out manufacturing and a chip-removal system.

Complex partsIan Foss, CNC programmer and machine shop supervisor at Rigging Projects, explained: “Prior to investing in our new Matsuura five-axis machine, we relied on three-axis machining centres and Y-axis lathes. We could make complex parts, but it would require multiple set-ups, nine or 10 in extreme cases. As we make most of our parts in small quantities, set-up was costing us a lot of time.”

Pictured right: Ian Foss, CNC programmer using Vericut

Pictured right: Ian Foss, CNC programmer using VericutThe five-axis Matsuura ensures Rigging Projects can make almost all of its components in a single set-up, saving significant time and cost. Mr Foss said: “In terms of complexity, the Matsuura is another level entirely. It was clear in my mind that, with such a high-value, we needed verification software to provide us with confidence during machining.”

Rigging Projects scrutinised various options for its verification software. Some were ruled out for reasons such as cost or lack of UK support, but Vericut ticked its boxes. Mr Foss had also used Vericut previously and could vouch for the software’s capabilities. He visited the

MACH 2024 exhibition in Birmingham with Chris Whitwam, head of engineering, to speak with the Vericut team, and the company never looked back. Rigging Projects duly invested in a seat of Vericut, offering Verification, Multi-Axis Machining, Machine Simulation and Auto-Diff capabilities. A cloud-based licence means that the two CNC programmers at Rigging Projects share the single seat. It also supports home working as necessary.

Complex parts are par for the course at Rigging Projects. Components that handle a line or sail cannot feature sharp corners, while meeting the high expectations of yacht owners also means aesthetic appearance is paramount. The company’s parts therefore feature many radii, rounded edges, curves and freeform surfaces, all of which means programs with plenty of 3-D surfacing.

Driven huge savingsMr Foss added: “We are far more about right-first-time machining and safety than saving every second in cycle time. The Matsuura has driven huge savings in set-up time, so now we just want to stay safe and avoid scrapping expensive workpieces. Vericut is a massive help in that regard.”

Every part programmed for the Matsuura using the company’s Autodesk Fusion 360 CADCAM software is run through Vericut. The Fusion 360 cascading post-processor integrates with Vericut to transfer manufacturing data, a capability that allows users to simulate and optimise NC programs in Vericut while continuing to work in Fusion 360.

He continued: “The whole process is seamless and Vericut simulation is a great asset. Fusion 360 has simulation, but it is a pre-post process and takes twice the time of Vericut. Moreover, while Fusion will flag up potential collisions, there is no tolerance-setting option. It won’t send an alert if the tool or spindle gets within 5mm of the table, for example. In contrast, Vericut will let me know if we get within whatever tolerance I set. I can subsequently refine the gap as confidence grows.”

Pictured left: Vericut verification provides confidence when machining in five axes of motion

Pictured left: Vericut verification provides confidence when machining in five axes of motionThe value of Vericut’s ability to avoid collisions on expensive machine tools should not be underestimated. Repairs to hardware such as spindles are extremely costly, as is machine downtime. Furthermore, a company like Rigging Projects would be forced to create new programs for other machines while waiting for the repair. Avoiding just one collision will likely more than cover the cost of Vericut.

Mr Foss revealed: “We have already had an incident when Vericut saved the day. We encountered an isolated issue with the Matsuura post-processor where it failed to pick up the work co-ordinates after a homing routine to re-orient the table. It used the machine co-ordinates instead, which means it would have tried to machine itself! Thankfully, Vericut picked it up and we rectified the issue. It saved a lot of money that day and avoided a potentially dangerous situation.”

Another valuable use of Vericut at Rigging Projects is AUTO-DIFF. Applied after simulation, AUTO-DIFF makes sure the CNC programmers do not miss any features and avoid major gouging or excess stock on the model that should be finished. The company also takes advantage of Vericut’s X-Caliper measuring tool, clicking on critical features to ensure that the programming of mid-limit tolerances meets with expectations, for example.

Mr Foss concluded: “With such a large, fast, five-axis machine like our Matsuura, Vericut is an insurance policy. Moreover, with its pallet-change capability, we often leave the machine running overnight. Knowing we have Vericut as a safety net provides real peace of mind.”