The range of 2-D/3-D measurement systems from the precision sensor manufacturer

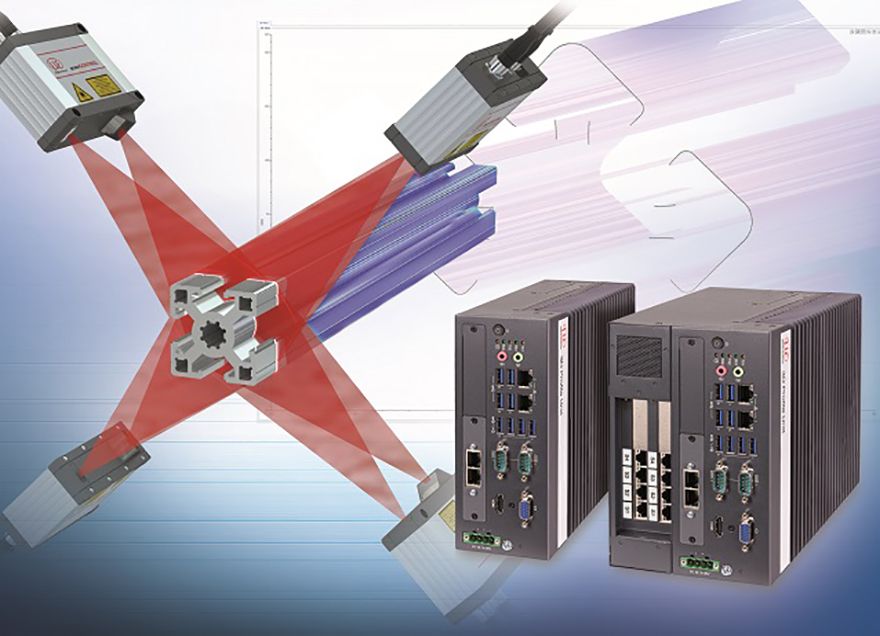

Micro-Epsilon UK Ltd, Birkenhead, has been extended with the company’s 3D Profile Unit (3DPU). This computer platform enables the calculation and profile stitching of up to eight individual profiles from the ScanControl 30xx series of laser profile sensors into a common coordinate system, thereby allowing a composite 2-D profile or a composite 3-D point cloud to be generated.

Explaining the need for stitching lines together, Micro-Epsilon said ScanControl sensors are available with a range of line widths from 25 to 788mm. “However, the number of measuring points is fixed across the line, which means the wider the line the greater the spacing in the X direction between points. Having the ability to arrange multiple sensors in a row and stitching those lines together allows for improved point spacing and/or improved coverage of complex geometries, such as the 360deg coverage of extrusions.

“With the 3DPU, a wide variety of geometries can be recorded, measuring ranges extended, and thickness measurements implemented, with the precise assignment of the position of each sensor to a common coordinate system carried out by registration; and after the sensors have been set up, the position of each individual ScanControl sensor is determined in a common overall coordinate system. This is referred to as multi-sensor registration and brings the individual sensor readings into a common coordinate system during the set-up process.”

Micro-Epsilon offers an individual registration target for each measuring range of the ScanControl sensors and for each measuring arrangement, although a special registration target can be designed for individual configurations and measurement setups.

Integrated fieldbus interfacesTwo versions of the 3DPU are available. The 3DPU-X system calculates the profile data of several ScanControl sensors into a common coordinate system and makes it available as 2-D profiles/3-D point clouds via GigE Vision, while the 3DPU-X/IE system compares the profile data of several ScanControl sensors into a common coordinate system, evaluates the 2-D profiles or 3-D point clouds and makes the measured values available via integrated fieldbus interfaces as a ‘good or bad result’.

Typical applications for the 3DPU include thickness measurement (using two opposing profile sensors) of battery film, smartphone carrier plates, and cold rolled steel strip. Using a linear arrangement of profile sensors, applications include checking the completeness of assembled PCBs, web edge monitoring, inspecting the dimensions of extruded square profiles, inspection of pins on automotive connectors, and the recording of road profiles.

Evaluation of data and parameterisation of the system is carried out using Micro-Epsilon’s 3DInspect software, which enables parameterisation of the 3DPU and the recording of measurement data directly from the software. Powerful tools allow the alignment and filtering of the point cloud, intuitive recognition and selection of relevant areas, as well as the combination of programs. 3-D point clouds can be processed as required, and measured values can be output to the controller.