AM Solutions – 3D post processing technology

AM Solutions – 3D post processing technology is set to make a major impact at

Rapid + TCT 2025 taking place 8-10 April in Detroit, with its advanced post-processing technologies for powder sieving and mixing, unpacking, support removal, cleaning and surface finishing of 3-D printed metal and polymer parts (Stand 3216).

With a broad portfolio of automated finishing solutions, AM Solutions is a key enabler of scalable additive manufacturing (AM) for production applications, helping manufacturers transition to full-scale production with cost-effective, high-quality solutions. The company is rapidly expanding its presence in the US market with a fully equipped 300,000ft

2 facility, providing post-processing solutions tailored for industrial AM users.

Dr Tayfun Sigirtmac, CEO at

Rösler/AM Solutions USA, said: “As a trusted post-processing partner for major AM players like HP, Stratasys, and EOS, AM Solutions is setting new standards for automation, efficiency, and repeatability in AM production. Our solutions help manufacturers reduce post-processing times and costs, improve surface quality, and enhance the mechanical properties of 3-D printed components, promoting AM as a viable alternative to traditional manufacturing.”

Visitors to the AM Solutions stand will get an exclusive look at three of the company’s many leading post-processing solutions, each designed to simplify and automate critical post-build finishing steps.

Automated and cost-efficient resin removalTaking centre stage will be the C1 system which is designed for photopolymer component post-processing, and provides automated and cost-efficient resin removal with precise, repeatable results. With integrated process monitoring, the C1 ensures consistent support structure removal and a superior surface finish, making it ideal for functional components, intricate prototypes, and design objects requiring exceptional detail.

Also on display will be the M1 Basic which is a versatile surface finishing system engineered for small- to medium-size AM production runs. It delivers consistent smoothing, deburring, and surface homogenisation, handling a variety of part geometries and materials to improve part quality across different AM applications.

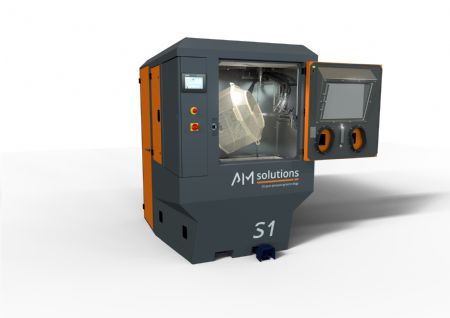

Completing the line-up will be the S1 system, a two-in-one solution combining cleaning and surface finishing, particularly for powder bed fusion (PBF) parts. It offers automated cleaning and surface finishing in a single, compact machine, reducing processing time by over 60% while improving production efficiency for high-volume AM applications.

AM Solutions will also highlight its strategic collaboration with EOS, which has resulted in the ongoing development of two groundbreaking post-processing systems: the D1 and F1. Designed for the EOS P3 series, including the new EOS P3 NEXT polymer printer, these solutions offer a fully automated workflow that streamlines unpacking, sieving, and powder mixing to ensure optimal material reuse and cost efficiency.

Industrial-grade standardsBy integrating automated unpacking and powder handling, the D1 and F1 systems minimise manual intervention and powder contamination, making them game-changers for scalable AM production. As EOS continues to advance polymer AM, AM Solutions’ post-processing expertise ensures that 3-D printed parts are finished to industrial-grade standards, supporting the transition from batch production to fully integrated serial manufacturing.

Moreover, the PowderEase T1, jointly developed by AM Solutions and Stratasys, will be showcased live at the Stratasys booth 2501. The collaboration between these two partners has resulted in an innovative three-in-one post-processing system for the Stratasys H350 SAF 3-D printer. The new PowderEase T1 combines unpacking, powder recovery, and powder dosing in a single unit, significantly simplifying workflows, reducing operating costs, and boosting overall productivity. One PowderEase T1 can serve up to six H350 3-D printers, minimising the need for additional equipment and labour. Compared to manual processes, the system saves up to 50min per print job, delivering substantial time savings.

At

Rapid + TCT 2025, visitors will also receive detailed information about the jointly developed 3D Automatic Unpacking Station from HP and AM Solutions. This scalable, industrial-grade post-processing solution enables the fully automated and reproducible unpacking of AM components from the HP Jet Fusion 5 series in a continuous workflow. In addition to a significant increase in productivity and greatly improved cost efficiency, it also achieves a considerably higher powder reclaim rate, depending on the geometry of the component.

Dr Sigirtmac concluded: “AM Solutions is a proven global leader in AM post-processing technology. With our 80-plus year heritage in surface finishing through our parent company, Rösler, and a ‘state of the art’ US facility with an integrated Customer Experience Center where visitors can see our post-processing solutions in action, we provide not just equipment, but fully optimised, automated finishing solutions that enhance quality, consistency, and efficiency. We are proud to be a preferred partner for post-processing automation, working with industry giants like HP, Stratasys, and now EOS, to ensure that AM parts meet the highest performance and aesthetic standards. We invite all

Rapid + TCT visitors to come and see us to see first-hand how our technologies can transform their AM workflows.”