Britain’s economic and productivity crisis can only be solved if we have a highly skilled workforce, embedded in the latest technologies and equipped with the skills to use them effectively, according to

Make UK. For that to happen, the manufacturers’ organisation says the Government and industry providers must “come together to deliver a dynamic knowledgeable workforce to compete competitively on the world stage, attract inward investment and deliver a robust industrial strategy”.

For the past five months, Make UK’s Industrial Strategy and Skills Commission has brought together business, employers, educators and policy makers to create a blueprint to train new and existing industry talent effectively.

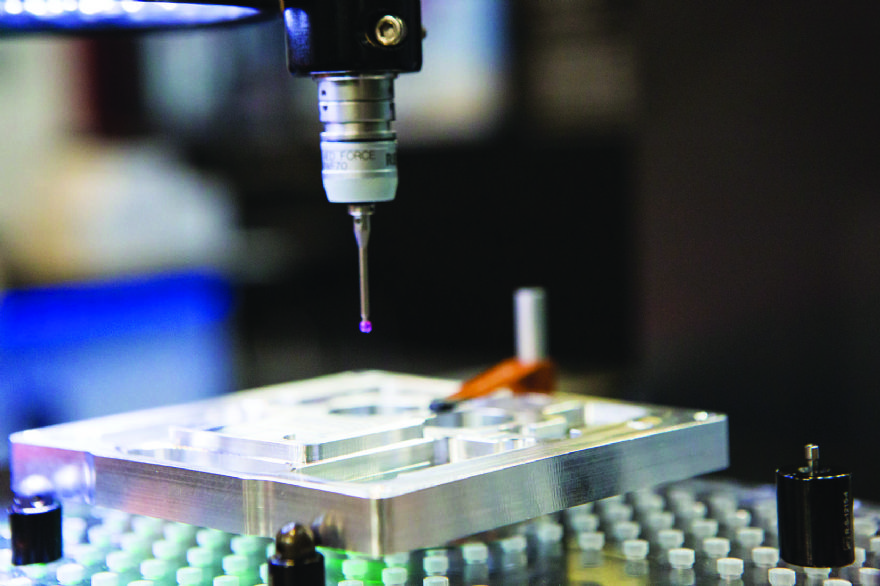

The UK has the sixth-largest economy in the world, but languishes at 24th in the robot density rankings because it lacks the workforce skills to adopt and apply these cutting-edge technologies. However, Make UK says that none of this can be turned around in the current climate, as manufacturing is in crisis with a dramatic rise in demand for upskilling at the same time as the pipeline for workers and teachers declines. Companies face a bleak landscape — an ageing workforce with early retirement on the rise, coinciding with a dramatic drop in apprenticeship starts — down 42% since the apprenticeship levy was introduced nearly eight years ago.

To begin to turn this around, Make UK says the Government and industry should agree a formal ‘Skills Covenant’, committing to increased investment on both sides in training and upskilling both the existing and future workforce. This must include short-term measures such as ringfencing skills funding. All revenue from the Growth and Skills Levy should be guaranteed for skills investment — including the £800 million the Treasury currently spends elsewhere.

The Government should also ensure that all revenue from the Immigration Skills Charge — which was more than £650 million last year — is spent on skills provision as was intended when the charge was first introduced. This £1.4 billion combined could fund 40,000 new engineers, going a long way to filling the 55,000 skills gap in the sector which is currently costing the UK economy £6 billion in revenue each year.

Work skills passportIn turn, manufacturers will commit to helping boost training availability through a workforce exchange, where companies will second staff to education providers. The sector will also commit to developing an electronic work skills passport, which will travel with employees to different roles and will keep a record of all qualifications gathered through their career; and businesses will commit to using the Careers and Enterprise Company Employer Standards to further develop their schools.

Extra pressure on the system comes from a dramatic decline in the number of education providers offering high-value courses, many of which have become financially unsustainable to run. Urgent legislation is needed to revise funding bands — including the level 3 engineers and technician apprentice position — from £27,000 currently to £35,000. This would reflect the real cost of delivering courses in engineering and highly skilled technical manufacturing. Rules should also be amended to allow training providers to draw on levy funds for capital investment in machinery and equipment, making it easier to set up capital-intensive subjects like engineering.

This lack of training availability is also hampering the pressing need for upskilling across the sector. Make UK research shows that over 50% of manufacturers intend spending more on upskilling and retraining their employees in the next five years, essential to growth and making inroads in the 55,000 skills gap in manufacturing. To boost essential retraining, Make UK says employers should have access to a tax rebate for investment in accredited skills training in key sectors and occupations identified by the Industrial Strategy Skills Council.

The Commission has also seen an urgent need to refocus careers guidance in schools and colleges to include information on apprenticeships and technical training. Alongside this, the University Technical College (UTC) model should be expanded to offer more technical routes to young people which would dramatically increase the sector’s talent pipeline.

AI revolutionRobert Halfon, co-chair of Make UK’s Industrial Strategy Skills Commission said: “Modern manufacturing and engineering are major drivers of the innovation needed to capitalise on the AI revolution and deliver on the Government’s growth agenda across new ‘green’ skills technologies and opportunities. Yet all of this is at risk if we do not urgently ensure our skills system is properly fit for the 21st century.

“It is critical that we remove the barriers for Britain’s innovative companies from offering skills and apprenticeships, so that the new Growth and Skills Levy provides enough quality apprenticeship opportunities that lead to progression and good employment outcomes. That is why financial incentives through a skills tax rebate, cutting bureaucracy and ringfenced skills funding will make a huge difference. The skills covenant will put skills and apprenticeships first and foremost in the minds of Government and business.”

Make UK’s CEO Stephen Phipson said: “The Apprenticeship Levy in its current form has been nothing short of a disaster. Apprenticeship starts in manufacturing have fallen by 42% meaning tens of thousands of learners have gone without invaluable training in the last eight years.

“The Government is sitting on a pot of cash that should immediately be ringfenced and spent on skills training. The first priority is properly funding courses, so colleges and training providers are not put off delivering higher cost courses such as engineering. There also needs to be targeted efforts to recruit experienced tutors to train up the next generation in the skills we need now and in the future.”