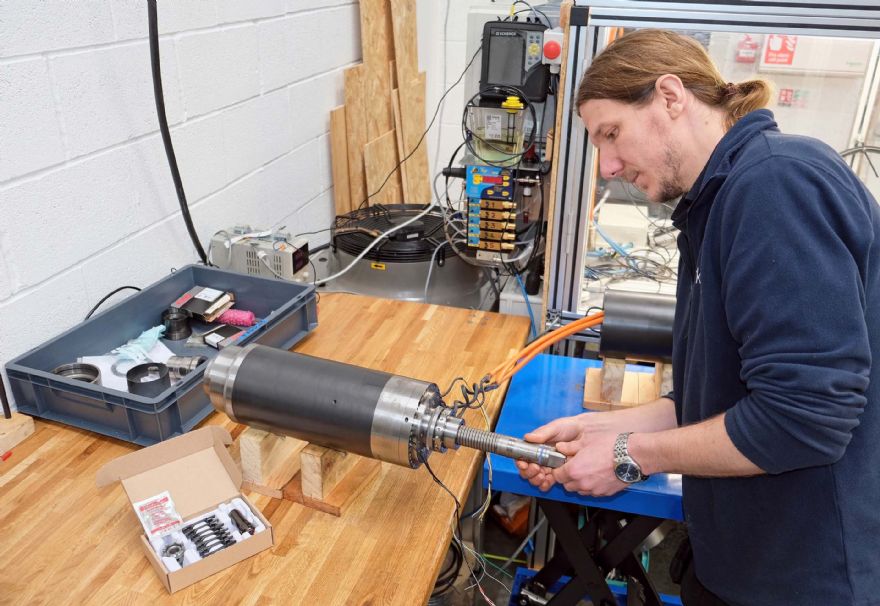

Stuart Vere, managing director of spindle repair and refurbishment company Kugel Rotary Services, show here inserting an OTT-JAKOB pulling head (drawbar) into an HSK-A63 milling spindle during its refurbishment

Stuart Vere, managing director of spindle repair and refurbishment company Kugel Rotary Services, show here inserting an OTT-JAKOB pulling head (drawbar) into an HSK-A63 milling spindle during its refurbishmentNottinghamshire-based

Kugel Rotary Services, a rapidly growing machine tool spindle repair and refurbishment company, moved in August 2024 from Sandiacre to new premises more than five-times the size in nearby Hucknall. The independent firm is one of only a handful in the UK to offer such a maintenance service across the full range of spindle types and sizes on the market, covering those produced by both specialist manufacturers and machine tool builders. Kugel customers realise savings of up to 50% compared with obtaining the service from the spindle manufacturer.

It is not commonly known outside this specialist sphere of activity that certain key elements of most spindles produced in Europe are made to the manufacturers’ designs by one of three third-parties, of which

OTT-JAKOB, located in southern Germany, is the largest. Kugel exclusively sources spares from this company, including the pulling head (drawbar), the clamping unit (the gripper in front of the spindle nose taper), and the rotary union (which attaches to the back of the pulling head to provide through-tool coolant delivery).

There is a long-term framework agreement between Gewefa UK and Kugel, whereby OTT-JAKOB components are supplied on a call-off basis

There is a long-term framework agreement between Gewefa UK and Kugel, whereby OTT-JAKOB components are supplied on a call-off basisUnderstandably, there is a close relationship between Kugel, OTT-JAKOB and the latter’s exclusive sales agent in Britain and Ireland, tool holder specialist

Gewefa UK, based in North Bradley, Wiltshire. It is a three-way relationship that was established when Kugel was set up in 2017 by managing director Stuart Vere and business partner Kevin Ewing, both of whom previously worked in a similar spindle and ballscrew renovation company. Mr Ewing’s son-in-law Alexander O'Neill and son David are also involved.

So too is Silke Moss, who also worked in the refurbishment company’s previous office in Sandiacre and is now the main link person between Kugel, OTT-JAKOB and Gewefa UK. She said: “The services Gewefa provides is amazing. It is exceptionally helpful with providing speedy quotes and trying to shorten delivery times when we receive urgent orders. OTT-JAKOB personnel also take a direct interest and have visited us. We can always contact the company directly with technical queries and for problem-solving — the whole relationship is based on mutual trust.”

The scope of Kugel’s activities is wide, centring mainly on spindles manufactured in Europe.

GMN,

Kessler,

Fischer, Gamfior,

Setco and

Step-Tec are some of the specialist spindle manufacturers whose products are routinely rebuilt, while

DMG Mori and

Heller are two machine tool builders whose in-house produced spindles are often overhauled. Japanese and other Asian versions tend to use different internal components, but some are easier to repair without the need for replacement parts. Recently, a Mazak spindle recently underwent refurbishment by Kugel.

Rebuilt spindles offer significant cost reductionsMr Vere explained: “We have a wide customer base, with 90% of our work currently coming from blue-chip companies in the automotive and aerospace sectors. They have production lines comprising numerous machine tools. If one goes down due to a spindle failure, the line stops. A situation that would just be an inconvenience to a sub-contractor down the road becomes an all-out emergency, with serious financial implications. The machine OEM or independent spindle manufacturer may well offer a service exchange and supply a refurbished spindle from stock. However it is an expensive option, added to which Brexit often delays the paperwork and increases costs further. We can rebuild a spindle in a similar lead time at typically between 50 to 75% of the cost.”

An HSK-A100 spindle repaired and tested in Kugel’s bespoke test rig in Hucknall. Accidental spindle collisions account for about one-fifth of repairs

The range of different spindles serviced by Kugel is vast, coming from many different machine tools including vertical and horizontal machining centres, borers, grinders, honing machines and lathes, for which both work spindles and B-axis tool spindles are repaired. Rotary tables and trunnions are also returned to as-new condition in Hucknall.

Similarly wide, is the variety of spindle sizes and specifications that are worked on, from a small 120,000rev/min high-frequency spindle for a die grinding customer, through HSK-A63 and HSK-A100 face-and-taper contact tool interface spindles and their taper-only contact BT 40 and 50 equivalents, to a special 300kg, 4000rev/min, two-in-one rough- and finish-grinding spindle for a specialist grinding machine manufacturer near London.

Routine preventative maintenanceThe present trend towards digitalisation in manufacturing and collection of large volumes of data for analysis means that sensors are often built into modern machine tools, including the spindle. Information on how long it has run since new or the last refurbishment, how many tool changes it has completed, at what range of temperatures it has operated in, vibration levels during use and other service-critical data is becoming more readily available. It heralds an age in which industry will move away from urgent spindle repairs after failure towards routine preventative maintenance, which can be carried out during shutdowns or less busy periods.

Even if machines are older and do not benefit from the wealth of operational ‘big data’ that their newer counterparts have, there are opportunities to train manufacturers’ maintenance staff and even machine operators to listen to the sound of the spindle, feel for vibration and perform other checks that could pick up signs of impending problems. Kugel is increasingly in discussion with customers using legacy machines about training programmes and the possible use of sensors for spindle monitoring as a basis for predictive servicing.

Trying to manage these scenarios and help prevent a spindle seizing up completely, hence significantly simplifying its restoration, is currently very much an area of interest and activity for Mr Vere. However, with so many older spindles in service around the UK that are likely to continue operating for a couple of decades, Kugel’s emergency repair service is set to continue growing for the foreseeable future alongside nascent scheduled maintenance activities.