Northumberland-based electronics manufacturer

Arian EMS has invested nearly £500,000 in ‘state of the art’ surface mount technology (SMT) equipment with the aim of significantly enhancing its manufacturing capabilities and offer more rapid turnround times. The company, which operates from a 16,000ft

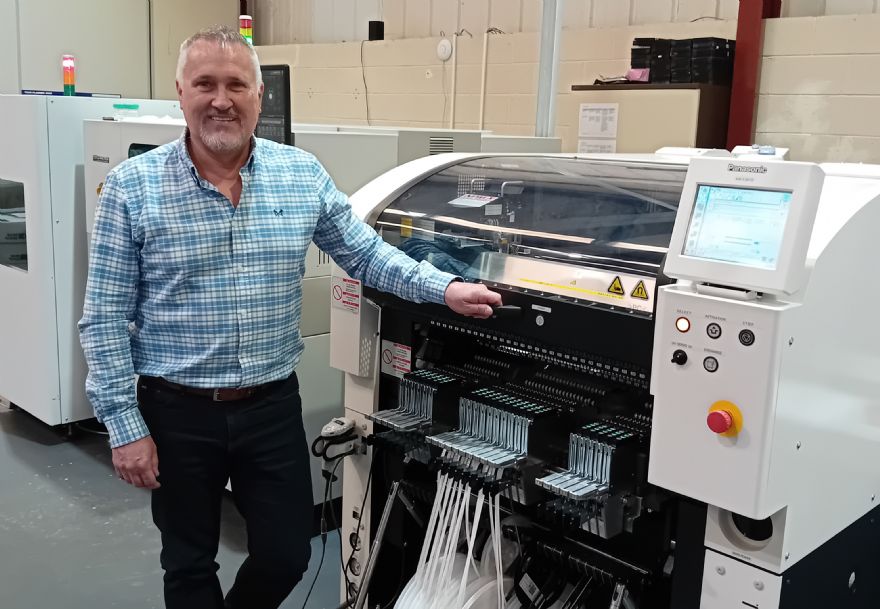

2 factory at Wansbeck Business Park in Ashington, has purchased two new electronics assembly systems — a Panasonic NPM-W2 machine and a Panasonic AM100 system.

This investment has been self-financed by the business and gives Arian EMS the capability to manufacture 50,000 to 100,000 printed circuit boards (PCBs) per month, and the capacity for 192 million chip placements per year on a single shift, doubling the current production capacity on its surface mount lines. The company has experienced year-on-year growth since it was founded in 2017 and is targeting a turnover of £12 to £15 million by 2030. The investment will strengthen the company’s ability to win additional contracts in sectors including defence and aviation, where fast turnround times and high-quality components are of paramount importance.

The Panasonic NPM-W2 integrates 3-D printing, placement and inspection processes and is optimised for larger PCBs and larger components. Equipped with a 12-nozzle head, it can place 38,500 chips per hour. The Panasonic AM100 system has been designed as a cost-effective, incrementally scalable SMT solution and is capable of placing large connectors, odd-shaped components and advanced packaging types.

World-class technologyMalcolm Humble, Arian EMS founder and managing director, said: “This investment is a major milestone for Arian EMS. It demonstrates our commitment to strengthening our Ashington facility with world-class technology, and to creating new job opportunities in North East England through further business growth. The integration of the Panasonic NPM-W2 and AM100 machines into our site reduces manufacturing cycle times by nearly 50% and brings a much higher level of efficiency to our surface mount department. This puts us in a strong position to support UK-based businesses wishing to onshore their component supply chains, and need a contract manufacturing partner that can deliver to tight deadlines ... and to the exceptional level of quality they require.”

Arian EMS supplies into a variety of sectors including automotive, security and medical, and its capabilities range from prototyping to high-volume manufacturing. The company also has extensive test facilities and offers device programming, 2-D inspection, automated optical inspection (AOI), in-circuit testing (ICT) and high voltage testing. It can also provide customers with full final assembly. Arian EMS has an established apprenticeship programme and recently took on two new apprentices, who are undertaking apprenticeships in finance and sales through Newcastle-based TDR Training.