norelem

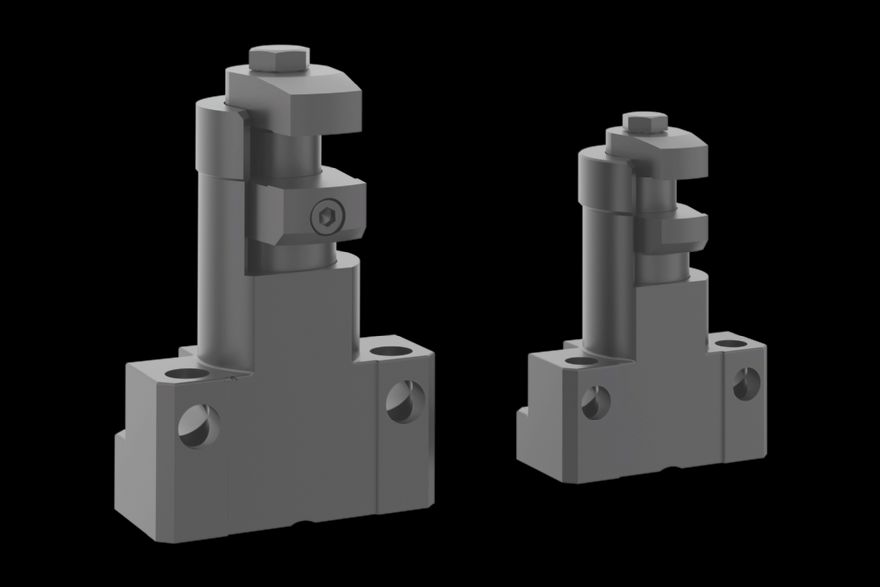

norelem has expanded its range of floating clamps with the introduction of a new, highly compact, in-house manufactured model for clamping and supporting components at over-determined clamping points. This latest floating clamp is available in two versions, offering enhanced versatility. The standard clamping jaw can be modified or replaced depending on the specific application.

Floating clamps secure workpieces in position using spring force, while allowing a degree of flexibility. This makes them ideal for use with thin-walled components that are prone to bending. They also help to reduce vibration and deflection during machining, making them particularly suited for blanks with fins or components with complex or irregular geometries. The ‘floating’ nature of the fixation provides the movement necessary for machining sensitive workpieces, ensuring precision and minimising clamping errors.

norelem’s new floating clamps are available in two variants: ‘Form A’ with fixed clamping jaws, and ‘Form B’, which offers interchangeable jaws. Form A is capable of generating clamping and supporting forces of up to 5,000N, while Form B delivers forces up to 8,000N. Both versions feature a base body made from nitrocarburised steel and end stops crafted from black anodised aluminium.

Operation is simple — the clamp is positioned beneath the workpiece by pressing it downward. The jaws then swivel fully into place, with the lower jaw coming into contact with the underside of the workpiece; the position is then secured by carefully tightening the hexagon nut within the specified torque range. At this point, the workpiece is both clamped and supported securely.