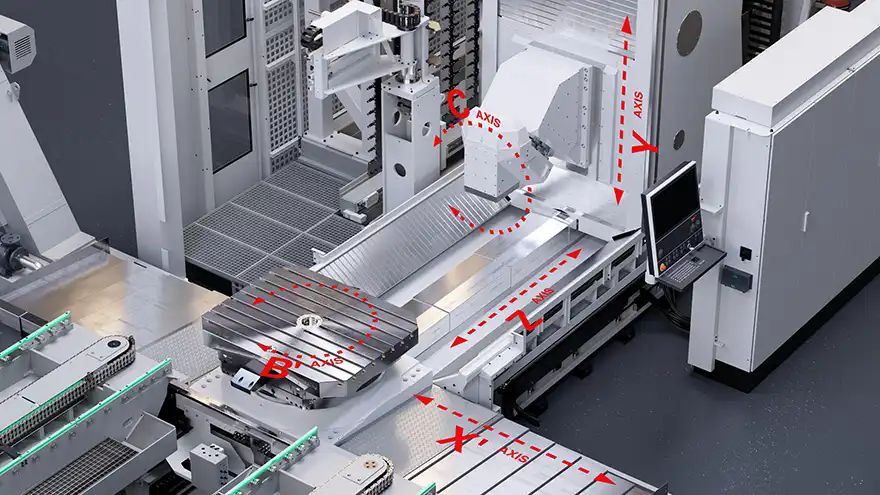

The work area of the next-generation S1250 machine from Starrag Heckert

The work area of the next-generation S1250 machine from Starrag HeckertGermany-based

Starrag, an industry-leading machine manufacturer from Chemnitz, unveiled its new large machine series in November 2024. The four planned models will be launched and presented to the market in stages throughout 2025.

Starrag’s HPMS (High Performance Machining Systems) business unit, which includes its Chemnitz and Rorschacherberg sites, has developed a new large machine construction kit from which new machining centres can be derived. For example, a Heckert large machine presented at an Open House in Chemnitz will replace the successful Heckert HEC Large Athletic series in the future.

The compelling reasons are based on the proven Heckert principles, such as rigidity and precision, which the company continues to hold as the highest priority. The movement sequences remain unchanged, and the advantage of this consistency is that the effort involved in transferring existing technology is limited. Operators of the previous Heckert HEC Athletic series will quickly adapt to the new machine models. Customers can also transfer devices and NC programmes without any issues.

The developers considered the latest technical aspects when redesigning the large Heckert machines. For example, the frame components, such as the beds and columns, were optimised for thermal symmetry. If the ambient temperature changes, the core components expand or contract evenly in all directions. This behaviour is predictable and correctable. The chip fall in the area between the work spindle and the workpiece has also been improved so that hot chips have minimal opportunity to transfer heat to the workpiece or the machine.

Improved productivityAn important advantage of the new machines is the improved productivity. The decisive factor here is an increase in the diameter of the ball screws from 63 to 80mm. A further stiffening of the structural components complements this. As a result, users can now achieve even higher cutting values, increase chip volumes and ultimately reduce machining times. The machine has also become faster. Instead of a 40m/min rapid traverse rate, it now enables 50m/min, reducing non-productive times.

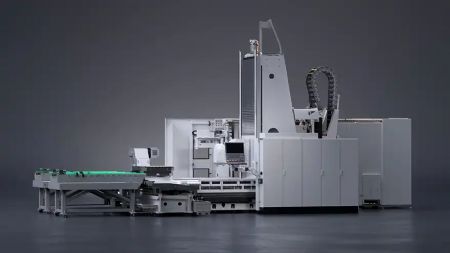

Pictured right: the new range of large Starrag Heckert machines

Pictured right: the new range of large Starrag Heckert machinesThe approximately 20% smaller footprint is another compelling argument in light of high floor space costs. This is primarily due to the repositioning of an energy chain, which enables the chip conveyor to be integrated further into the machine. Additional detailed improvements include structural changes that allow for a payload of 20 tonnes, thereby opening up new part families and customer groups. The Starrag developers also redesigned the energy console at the rear of the machine, consolidating all maintenance-relevant elements in one location.

The new Heckert large machines are designed as a modular construction kit with four predefined sizes, with all structural components being freely combinable with each other. This allows users to put together the optimum machining solution for their needs. The selection of spindle variants and heads is also extensive and set to expand. In the future, it will be possible to fit attachment heads to the quill and fork head that enable different geometries or speed changes.

The selection of tool magazines has also increased with the new machine series. In addition to the existing chain and tower magazines, the Starrag employees in Chemnitz developed a modular rack magazine that offers space for up to 828 tools. These may be up to 380mm in dia and 1,500mm long, weigh 100kg and have a tilting moment of 150Nm. The new tool management software ensures maximised packing density. It manages a reserved quick-change area near the tool changer, automatically ejecting tools when the tool life is reached. The intervention times of all tools are also documented.