Nikon Corporation

Nikon Corporation (Nikon) has launched the VOXLS 20 C 225, the latest addition to its VOXLS X-ray CT product line-up. This system is based on the proven principles of the company’s VOXLS 30 and 40 Series systems while offering maximum capability in a space-efficient footprint, providing unparalleled value per voxel in the market.

The VOXLS 20 C 225 offers the largest CT scanning envelope in a system that fits through a standard double door, allowing for flexible integration to almost any quality control laboratories and production environments. The new system features Nikon’s metrology-grade platform with a granite base, rigid steel manipulator towers, and high-accuracy encoders and motors. These engineering choices ensure the precision, repeatability, and reliability that the Nikon brand is known for while delivering exceptional X-ray and CT data quality.

Key features include: superior CT inspection envelope — offers an industry-leading inspection volume of 555m dia x 759mm height in a compact footprint of just 2,451mm long x 1,173mm dia; a motorised dual-source set-up with a 225kV reflection target and 160kV transmission target, allowing users to choose the optimal source for their application at the push of a button — this enables automated and fast switchover between the reflection target (for higher productivity due to increased X-ray flux) and transmission target (for achieving the best possible resolution); it de-skills the process of setting up the filament for optimal performance, simplifies the filament change process, and provides longer filament lifetime; offers enhanced usability with features such as ‘Filter Changer’, motorised door that opens in under 4sec, and large viewing window for excellent interior visibility; and supports Motorised FID and advanced scan modes including Panel Shift CT, Tilted CT, and Pixel Split CT, enabling a wide range of inspection techniques for diverse applications.

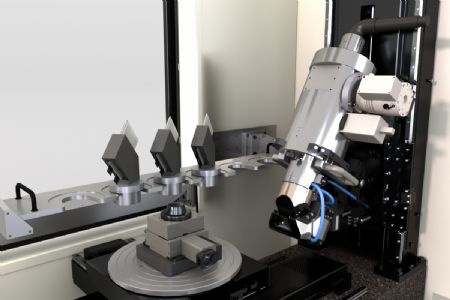

Pictured right: Nikon VOXLS 20 C 225 autoloader, Automation Ready

Pictured right: Nikon VOXLS 20 C 225 autoloader, Automation ReadyThe first Nikon VOXLS 20 C 225 systems are scheduled for delivery this autumn and will serve industries including electronics, additive manufacturing (AM), aerospace, automotive, and medical devices. Ben Morgan, product manager at Nikon, said: “Our customers have been seeking a comprehensive X-ray CT solution that combines advanced capabilities with space efficiency. The VOXLS 20 C 225 delivers precisely that — with its industry-leading inspection envelope, innovative features like X.Tend Helical, Scatter Correction CT, AI Reconstruction, and dual-source configuration with Rotating.Target 2.0, we have created what we believe is the most capable and versatile X-ray CT system in its class.”

Designed as a long-term investment, the VOXLS 20 C 225 is ready to adapt to the evolving needs of a high-end manufacturing business. Whether in the laboratory or on the factory floor, the new X-ray CT system is equipped with innovative technology for increased throughput and is upgradable with a range of automated and robotic inspection solutions using Nikon Automation with OPC UA Interface.