A high-tech company offering manufacturing solutions in the fields of machine tools and laser technology,

Trumpf has developed new high-productivity fibre lasers that are suitable for a wide range of welding applications, including the high-precision welding of batteries for electric vehicles (EVs).

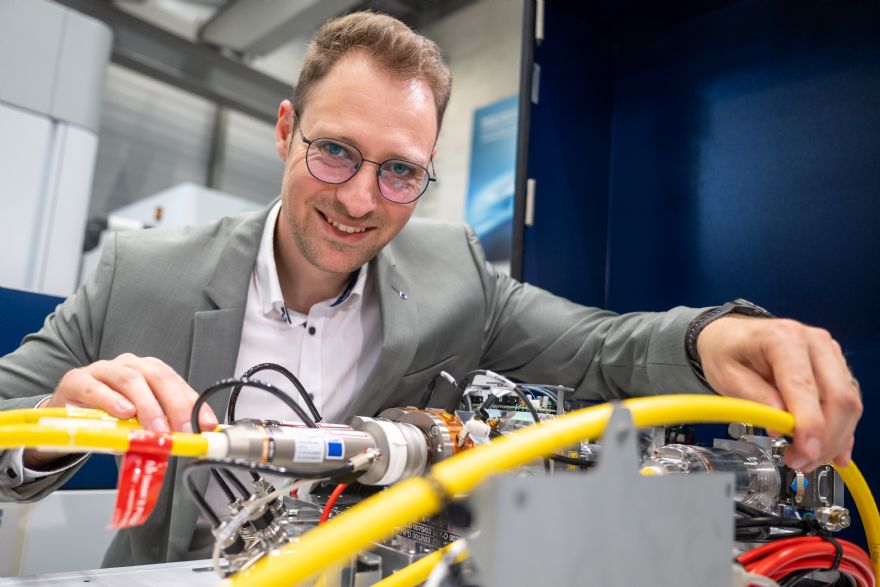

Tom Rentschler, Trumpf’s product manager responsible for the new fibre laser series, which was launched at the leading trade fair

LASER — World of Photonics in Munich, said: “The new generation of TruFiber lasers is at the heart of our production solutions. Together with our programmable optics and sensor technology, they enable users to increase productivity in their manufacturing and improve the quality of the components they produce.

“Users can order the TruFiber in power classes from 500W to 50kW and combine it with Trumpf’s complete laser system technology. This includes focusing optics such as scanners and fixed optics, as well as solutions for monitoring the status of the entire system. Lasers, controls, beam guidance, processing optics, sensors, and cooling, are optimally coordinated at Trumpf, with dynamic power control ensuring precise and repeatable weld seams; this is advantageous when welding copper, for example.

“The complete integration of control and optics, as well as its robustness, make the new TruFiber with its high beam quality the ideal tool for industrial applications where precision and efficiency are crucial.”

Mr Rentschler went on to say that, thanks to integrated sensors, many of the laser’s functions can already be monitored remotely, thereby eliminating potential errors in the welding process. “If a Trumpf service technician does need to visit the system, the modular design of the laser allows them to replace all components quickly and easily on-site, saving users time and money. Furthermore, the user interface and programming of the control system are particularly intuitive, with operation like that of a smartphone; this interface greatly simplifies laser material processing.”