TaeguTec WinSwiss head replacement system

TaeguTec WinSwiss head replacement systemCutting tool specialist

TaeguTec has introduced an innovative Win-Swiss modular head and holder system which has been specifically designed to enhance productivity and efficiency in Swiss turning centres, by tackling the industry’s longstanding challenge of time-consuming insert changes, while at the same time improving the rigidity and precision requirements of the sliding-head turning market.

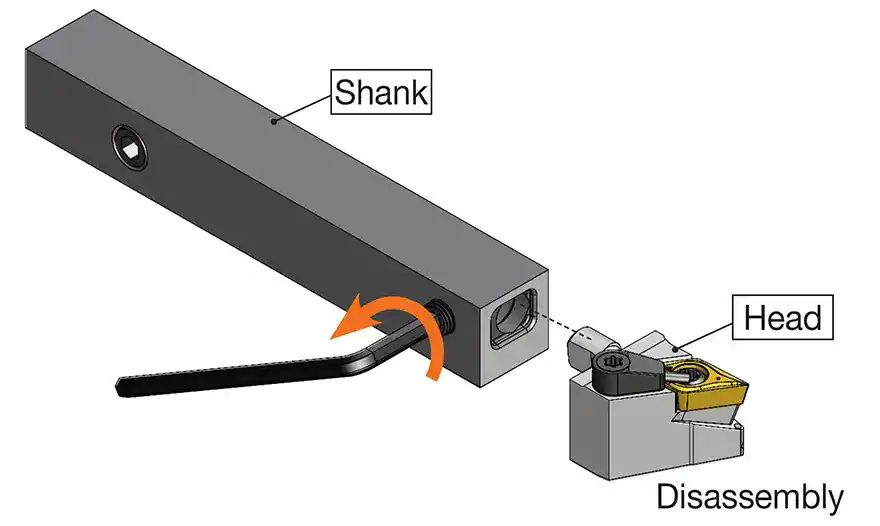

The Win-Swiss system represents a paradigm shift in Swiss machining methodology. It allows operators to change inserts outside the machine by detaching only the modular head while the shank remains securely attached to the toolpost. This innovative approach eliminates the necessity for the complete removal of holders, significantly reducing setup time and minimising production downtime.

Performance testing shows that the Win-Swiss system achieves an impressive 77% reduction in tool change time compared to conventional holders, reducing typical changeover periods from 108sec to just 25sec. This substantial improvement directly translates to enhanced productivity and lower manufacturing costs for precision machining operations.

Pictured right: the TaeguTec WinSwiss in action

Pictured right: the TaeguTec WinSwiss in actionThe Win-Swiss system incorporates TaeguTec’s proprietary fastening technology, which features a unique combination of screw clamping and tapered face contact, delivering machining stability comparable to conventional integrated holders. The robust assembly mechanism utilises a taper design combined with lever principles to ensure rigid clamping between the tool shank and the heads. This design provides exceptional repeatability while maintaining dimensional deviation within +/-5µm, all while requiring only a single rotation of the clamping screw.

The modular design philosophy extends beyond mere convenience, providing significant inventory benefits through the ability to mount multiple heads on a single shank. This flexible interchangeability enables manufacturers to optimise their tooling investments while maintaining comprehensive machining capabilities across various applications.

Selection of modular headsThe Win-Swiss range features a comprehensive selection of modular heads tailored to Swiss turning requirements. External turning applications are supported by the TopMini, RhinoTurn, and RhinoMTurn (QE1-SDJCR, SDJNR, SVJBR, and SVJCR) series, each engineered with 93deg approach angles and compatible with industry-standard insert geometries. The QE1Y-SDJCR series provides specialised Y-axis machining capabilities. This innovative line has been specifically designed for complex multi-axis operations that are commonly found in Swiss turning centres.

The QuadRush (QE1-TQHR and TQHL) series addresses parting and grooving requirements, offering unparalleled precision for these essential operations. The T-Clamp (QE1-TTER and TTEL) series for external turning, grooving, and parting offers various insert chip-breakers to accommodate a wide range of workpiece materials for a broad selection of cutting parameters.

Back-turning operations, often challenging in compact Swiss turning work envelopes, are fully supported by the TopMini (QE1B-SVXCR) series, which features optimised geometry for enhanced cutting performance and accessibility that significantly reduces tool changeover times.

The Win-Swiss system features TaeguTec’s COOL-BURST high-pressure coolant delivery technology, which provides both top and bottom coolant supply, denoted by the -TB suffix. This sophisticated cooling system directs concentrated high-pressure coolant precisely to the cutting edge, greatly enhancing chip control, prolonging tool life, and facilitating higher machining parameters. The precise internal coolant delivery system guarantees consistent performance in demanding applications while preserving the system’s modular benefits.

TaeguTec has engineered the Win-Swiss system with an error-proof assembly mechanism that prevents incorrect head and shank combinations. This design feature eliminates the risk of improper assembly while ensuring optimal performance characteristics. The system’s design philosophy prioritises operator safety and ease of use by minimising the risk of losing spare components and inserts during simplified changeovers, a common concern with traditional integrated holders.