Ceratizit will focus on powerful tool solutions, digital services, and numerous product innovations that simplify everyday machining tasks at

EMO Hannover 2025 (Stand B42, Hall 5). Where some competitors merely supply tools, Ceratizit has positioned itself as a partner along the entire value chain — from the development of innovative carbides to precise tool production and recycling, the company supports its customers with tailored solutions.

At

EMO, this approach will be demonstrated with practical machine simulations showing how close collaboration leads to individual tool and process solutions for key industries including automotive, aerospace, heavy duty, hydraulics, and consumer electronics. Furthermore, Ceratizit experts will be on hand throughout the show to offer advice and have discussions with visitors.

A special focus of Ceratizit’s appearance at

EMO will be on digital applications. With ToolSelect, the tooling company introduces a solution that takes the selection of the optimal machining strategy to a new level — users can either manually enter workpiece data or upload a 3-D model, and within 90sec, the system provides up to five suitable tooling combinations for milling, drilling, turning, or grooving operations. ToolSelect is fully integrated into the Ceratizit online shop and offers extensive comparison, filter, and sorting functions for precise fine-tuning.

Strategic investmentThe digital portfolio is also complemented by the Spanflug BUY and Spanflug MAKE applications, which are now part of the Ceratizit offering through a strategic investment in Spanflug Technologies GmbH. These tools enable even more precise quote calculations based on detailed tool data and open up new synergies in product development, sales, and internationalisation.

At

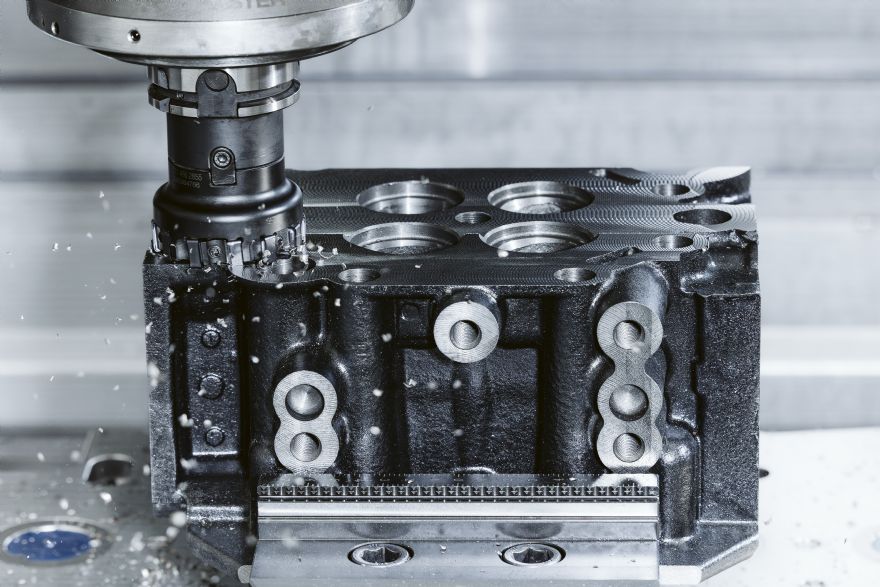

EMO, Ceratizit will present several innovative tools, including the MaxiMill S-Power milling system for cast materials, the MonsterMill ISO-S for nickel-based alloys, and the versatile WTX-UNI drill series. All innovations are characterised by high tool life, optimised geometries, and sustainable materials – developed for maximum efficiency and process reliability in demanding applications.

Meanwhile, the CoreLine series (pictured left), Ceratizit demonstrates what powerful standard solutions with high quality and attractive price-performance ratios can look like. This product line is specifically aimed at general machining and offers a wide range for small to medium batch sizes – supported by simple ordering processes and short delivery times.