Stratasys Ltd

Stratasys Ltd, a global company that develops additive manufacturing (AM) systems, is working with

Toyota’s production engineering group to enable automotive workers to seamlessly integrate 3-D printing technology in their manufacturing process, taking tools, fixtures and jigs from initial concept to working prototype in just one day.

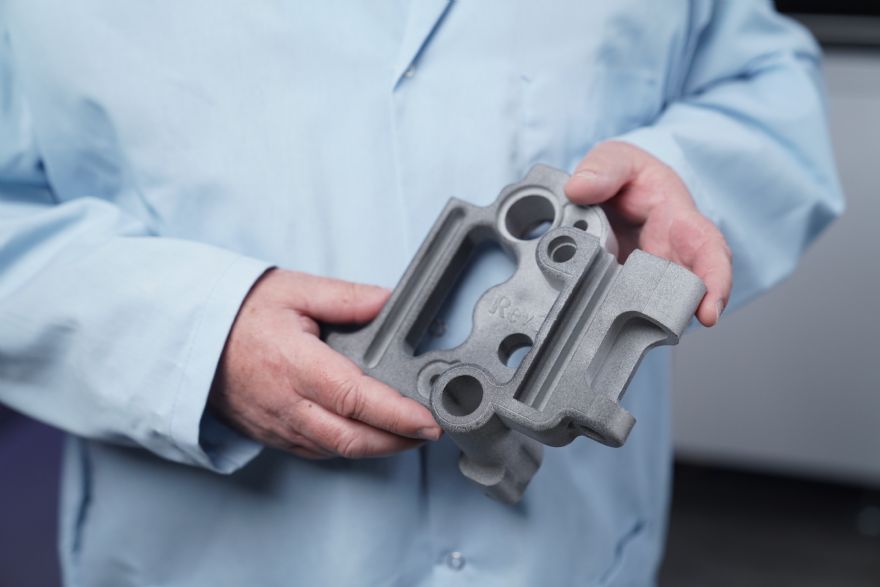

Toyota is currently using Stratasys’ F3300, F900, Origin One, F770, Neo800, H350, F370, J850, and Fortus 450mc printers to produce robust factory tooling, end-use parts, and functional prototypes throughout its North American facilities. Indeed, Toyota says it can transform ideas into durable, customised tools that support workflows, enhance worker safety, and withstand wear and tear, adding that much of this work is powered by the Toyota Add Lab — the company’s in-house additive manufacturing (AM) centre that was opened in January 2023 and is ‘dedicated to accelerating R&D and factory innovation’.

Dallas Martin, an AM engineer at Toyota North America, said: “Sometimes we start with nothing more than a sketch on paper or an idea in our heads. We then model the concept digitally and have a working part in our hands the very next day. That speed lets us move quickly, implement safer solutions, and continuously iterate to improve our processes.”

The tools to think differently and act immediatelyLisa Bednar, group manager of production engineering at Toyota North America, added: “AM has transformed how our teams collaborate and innovate. Instead of sending an idea to an external company and waiting weeks for a part, we are building it ourselves, refining it the same day, and getting it into production faster. It is not only about speed but also about giving our people the tools to think differently and act immediately.

For example, we have used 3-D printing to redesign a door assembly fixture, creating a lighter, more ergonomic tool on-site in just a few days. In another case, we developed a custom window alignment jig that turned a multi-person job into a one-person task, boosting both safety and efficiency.”

Rich Garrity, Stratasys’ chief industrial business officer, said: “Toyota is a stand-out example of how leading manufacturers are leveraging AM to deliver meaningful operational impact. The company’s teams are using our technology to move faster, adapt on the fly, and build safer, more efficient production environments — turning bold ideas into real-world, measurable improvements on the factory floor.”