Nova Laboratories’ in-house machine shop

Nova Laboratories’ in-house machine shopLeicestershire-based

Nova Laboratories, a privately owned pharmaceutical company, has significantly enhanced the productivity and efficiency of its in-house machine shop following the adoption of BobCAD-CAM software and dedicated programmer training delivered by

Mills CNC’s Training Academy.

The decision to invest in advanced CAD-CAM technology has proved transformative. Precision prototype parts and finished components—integral to Nova’s pharmaceutical processing and production machinery—are now being machined faster, more accurately, and more cost-effectively. This improvement supports both the company’s own licensed products and its expanding contract manufacturing operations.

The machine shop, once a modest adjunct to Nova’s core pharmaceutical business, now plays a central role in the company’s production strategy. To understand its importance, it’s worth revisiting the origins of Nova Laboratories.

Founded in 1993 by Dr Peter White and a team of NHS pharmacy colleagues in Wigston, Nova Laboratories was established to manufacture pharmaceuticals more safely and efficiently. The company pioneered the use of gassed isolator technology and aseptic manufacturing processes, setting new standards in sterile production environments.

Contract manufacturing serviceToday, Nova designs and manufactures its own licensed medicines in-house, including treatments for Acute Lymphoblastic Leukaemia (ALL), Sickle Cell Disease (SCD), and Inflammatory Bowel Disease (IBD), which are distributed globally. Alongside this, its contract manufacturing service continues to grow, offering customers bespoke aseptic processing solutions — from sterile ‘fill and finish’ lines to crimping systems for clinical trial and commercial products.

To support these operations, Nova Laboratories designs and often manufactures its own R&D and production-line equipment. Specialist machinery, such as isolators, is built to exacting specifications, and ensuring minimal downtime across production lines is critical. This is where the machine shop comes into its own.

Initially established in 2018, Nova’s machine shop was born out of a desire to control quality, reduce lead times, and manage costs more effectively. Rather than outsourcing, the company acquired a small engineering workshop adjacent to its main facility. Retaining some manual machines and hiring experienced machinist Steven Potter to oversee operations, Nova began building its machining capabilities from the ground up.

Investment in the shop has been continuous. A new, purpose-built facility was constructed, and CNC capacity was expanded with the addition of two Fanuc-controlled machines: a Doosan Puma 2100Y II multi-tasking turning centre with Y-axis and driven tooling, installed in 2019, and a used Doosan DNM 500 vertical machining centre (VMC) added in 2020.

However, as Steven Potter explained, unlocking the full potential of these machines required more than hardware: “We had already invested in CAM software to create programs for the DNM 500, but needed something different and more bespoke for the Puma 2100Y. Although it was possible to programme the machine directly using the onboard EZ Guide system, this approach had its limitations — especially when machining complex, high-precision 3-D components with intricate features and details.”

With demand increasing for such parts, and with quality and speed paramount, Nova recognised the need for a CAD-CAM system tailored to mill-turn applications. Potter led the search, drawing up a checklist of essential features. He recalled: “It was important that we invested in a system that would meet our immediate and future needs. The CAD-CAM system needed to be powerful and flexible, capable of handling 2-D and 3-D part processing, be easy to understand and use, and be competitively priced.”

Having already established a strong relationship with Mills CNC — both through the purchase of the Puma 2100Y and participation in a Fanuc programmer training course — Nova turned to the CNC Training Academy for guidance.

Mr Potter said: “CNC Training Academy staff were really helpful. Although we had heard of BobCAD-CAM, we didn’t really know that much about it. Having contacted Darren Clarke, BobCAD-CAM product manager at the Academy, a presentation on the system was arranged where its features and benefits would be demonstrated and explained to us in more detail.”

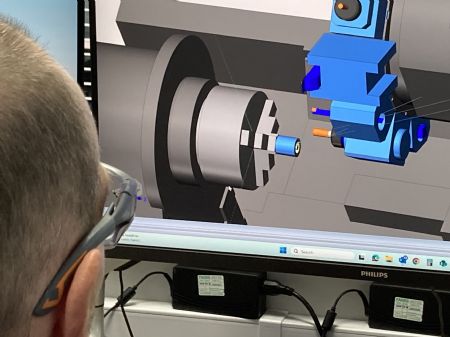

Powerful and flexible solutionThe presentation impressed. With the Academy acting as a licensed UK reseller and offering on-site training, Nova Laboratories opted to invest in BobCAD-CAM — and hasn’t looked back. BobCAD-CAM offers a powerful and flexible solution with a user-friendly interface and advanced toolpath options for 2D, 3D, and multi-axis machining. Its full 3-D simulation capabilities allow users to optimise toolpaths, detect programming errors before machining, and ensure fast, accurate, and reliable production.

The system also includes robust CAD functionality for creating and modifying product designs, making it a comprehensive tool for Nova’s evolving machining needs. While BobCAD-CAM offers robust CAD functionality, Nova Laboratories primarily leverages the software for its CAM capabilities. As Steven Potter explains, the company’s design engineers use AUTODESK Inventor for product development and prototyping — a sophisticated CAD platform well-suited to Nova’s pharmaceutical engineering needs.

Mr Potter continued: “We use BobCAD-CAM more for its CAM, rather than CAD, functionality. Our machines and equipment are designed in-house using Autodesk Inventor. Completed 3-D CAD files can be exported to BobCAD-CAM for editing and design modifications if needed, or imported directly into the CAM system for toolpath creation, machining strategy selection, and parameter optimisation.”

Once simulation and G-code generation are complete, the verified programs are transferred via USB to the Puma 2100Y, enabling fast and accurate part production. The machine shop has handled a wide range of components using BobCAD-CAM, many of which are urgent or emergency jobs. These include original, replacement, and spare stainless steel (316) parts for Nova’s newly designed pharmaceutical isolators. Among them are airflow control and venting system components—high-precision machined nozzles, couplings, connectors, and fittings—all manufactured to exacting standards.

Mr Potter is unequivocal about the impact of the software on Nova’s operations. He said: “The investment in BobCAD-CAM has been positive and has improved our quality and response times. From effectively a standing start, we are now able to make parts faster, better and more economically than before on the Puma 2100Y. BobCAD-CAM has been instrumental in helping us improve our process efficiencies and increase our productivity, and is helping us better exploit the machine’s part processing potential.”

He concluded: “Furthermore, BobCAD-CAM has also helped both elevate and strengthen the machine shop’s position in Nova Laboratories’ in-house production chain.”