Rösler UK

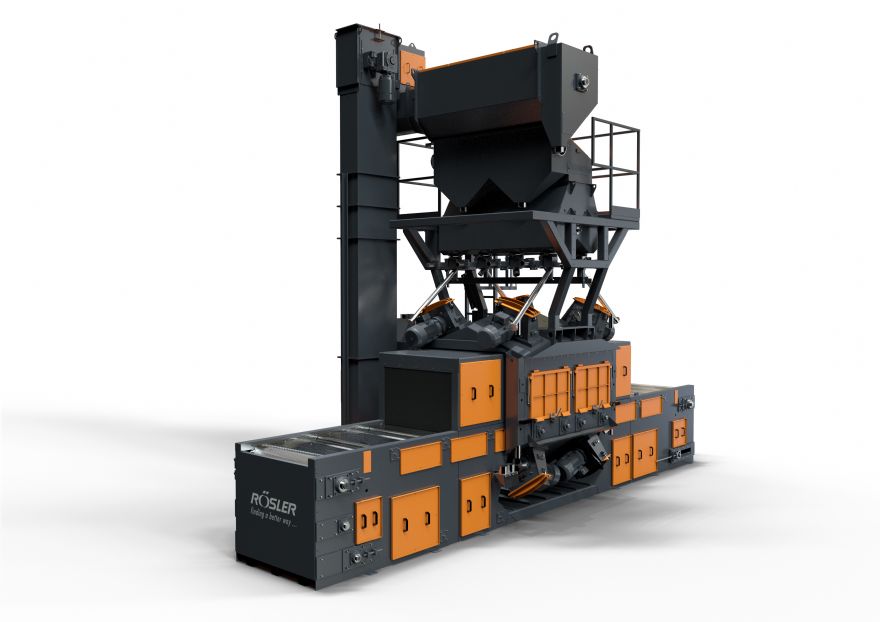

Rösler UK has announced that its advanced RDGE wire mesh belt shotblast machine is now fully operational at its ‘state of the art’ Customer Experience Centre (CEC) in Knowsley, a major milestone in the expansion of the site’s capabilities and a huge opportunity for UK manufacturers.

The RDGE machine is widely regarded as one of the most flexible and effective continuous flow shot blasting systems on the market. Its arrival at the CEC is a game-changer for Rösler’s customers in the UK, who can now see this highly efficient, precision-engineered machine in action, and crucially, benefit from its capabilities through the CEC’s sub-contract finishing service.

Dave Williams, sub-contract manager at Rösler UK said: “The RDGE gives us a new level of versatility and throughput in our sub-contract operations. We can now offer continuous shotblasting for flat and geometrically complex components with consistent, all-round surface treatment, whether for descaling, derusting, deburring or pre-coating preparation — it is big news for our customers.”

High-productivity environmentsThe RDGE’s technical features are tailored to the demands of high-productivity environments. Designed for continuous flow operation, it accommodates variable transport speeds between 0.6-6m per min on a highly wear-resistant wire mesh manganese steel belt. Optimally placed turbines (configured through computer simulation) ensure uniform blasting results with minimal shadowing, even for large or intricately shaped parts.

As part of the CEC offering, the RDGE joins an extensive range of mass finishing, shotblasting, and AM post-processing systems that support customers among others in aerospace, automotive, medical, and defence sectors. Whether developing new finishing processes, validating surface performance, or outsourcing production-scale surface treatments, the CEC has become a vital hub for finishing innovation and problem-solving.

Mr Williams added: “Having this technology onsite means we are not just talking about what is possible, we are proving it, live, every day. For customers, it is a low-risk way to explore advanced finishing without immediate investment, and for Rösler, it reinforces our commitment to delivering real-world results.”

The RDGE’s integration into the Knowsley CEC underscores Rösler’s position as a total solutions provider, offering not just machinery, but expertise, process development, and full-service finishing support.