DMG Mori will demonstrate how the LASERTEC DED hybrid and LASERTEC SLM AM technologies can be seamlessly integrated into end-to-end additive manufacturing process chainsDMG Mori

DMG Mori will demonstrate how the LASERTEC DED hybrid and LASERTEC SLM AM technologies can be seamlessly integrated into end-to-end additive manufacturing process chainsDMG Mori will be exhibiting its 3-D printing technologies at

Formnext 2025, taking place in Franfurt from 18-21 November (Hall 12, Stand D139). The machine tool manufacturer will demonstrate how its additive manufacturing (AM) systems, both the LASERTEC DED hybrid machines for laser deposition welding and the powder-bed models in the LASERTEC SLM series for layer-by-layer manufacture, may be optimised for the series production of metallic components. The company will show how both technologies can be seamlessly integrated into end-to-end AM process chains.

As part of its MX machining transformation strategy, the manufacturer focuses on production in one clamping. Accordingly, LASERTEC DED machines reduce throughput times by employing a six-in-one process that includes preheating, AM using a powder nozzle, 3-D scanning, milling, turning and grinding.

The ability to switch between additive and subtractive technologies allows the creation of complex geometries and multi-material parts that can be endowed with bespoke properties, such as better wear or corrosion protection, or increased resistance to chemicals. AM components often have a long service life and require little maintenance, so their availability is maximised.

Pictured left: The machine tool manufacturer optimises the hybrid machine process chain with intelligent technologies

Pictured left: The machine tool manufacturer optimises the hybrid machine process chain with intelligent technologiesFurthermore, reheating minimises stress and prevents cracks between the base material and the deposited weld material, resulting in good mechanical properties. A 3-D laser scanner enables precise, non-contact quality control through false colour imaging. The optional use of blue lasers expands material inspection to include highly reflective metals such as copper and allows graded material transitions for the production of highly functional components. At the end of the process, precise finishing is possible on the same platform, all steps being flexibly combined and repeatable.

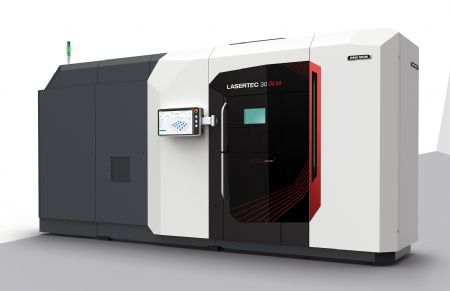

With the latest Lasertec 30 SLM third-generation powder-bed AM machine, DMG Mori has introduced an interchangeable build chamber to eliminate one of the biggest bottlenecks in metal 3-D printing, namely long cooling times after completion of the process. The chamber may be removed and replaced with another, pre-prepared chamber without having to wait, so production can continue almost without interruption.

Setup times are significantly reduced, as preparation of the chamber is performed away from the machine. This not only eliminates the need for repeated flooding of the chamber with inert gas, but also lowers consumption of the shielding gas. An integrated lid increases safety and preserves the protective atmosphere between jobs, allowing powder management and material handling under inert gas conditions.

Robustness and repeatabilityThe third-generation selective laser melting platform combines robustness and repeatability with thermal stability, as it has a rigid cast structure based on the materials and design principles of the majority of DMG Mori's milling and turning machines. The 325 x 325 x 400mm build volume has been sized to appeal to a large section of the intended market.

At

Formnext 2025, DMG Mori will be presenting the new rePLUG FLEX, a simple version of the proven rePLUG powder module. This variant does not require a closed powder circuit within the machine. Material change can be carried out without an additional powder module, which is an economical solution, especially for materials that are only used in small quantities.

The LASERTEC 30 SLM can be operated easily and intuitively due to the incorporation of the CELOS X digital interface with easyAM. Camera-based monitoring of the powder bed ensures high component quality and minimises process interruptions. After each layer has been laser melted, the surface is scanned for anomalies and analysed. A heat map visualises possible defects and an evaluation system is used to assign an anomaly score to the layer. The graphical representation allows the operator to check all layers built up to that point.

A new feature is the ability to project layer data from the workpiece CAD file onto the respective camera image. This makes it easier to assess whether a detected defect will actually have an impact on the function of the component or is limited to non-critical areas. Using the real-world example of a cobot end effector for DMG Mori’s MATRIS Light machine tool-tending system (pictured right), the company will demonstrate the complete production process at

Formnext 2025.