RA Rodriguez (UK) Ltd

RA Rodriguez (UK) Ltd has supplied high-performance gears for

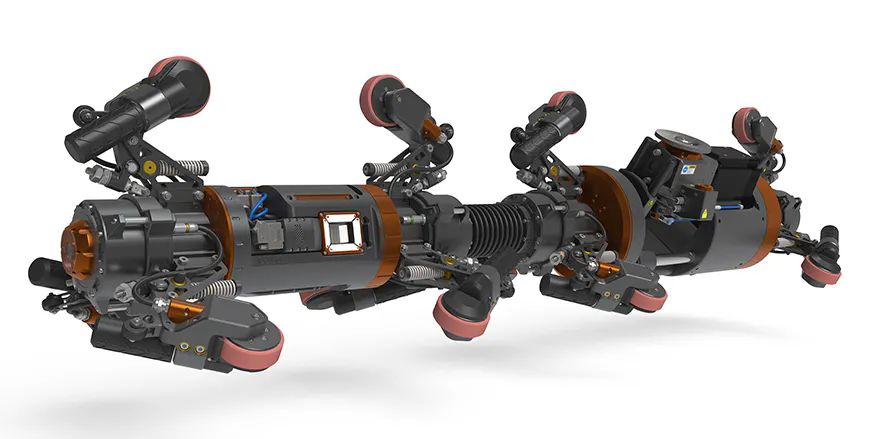

OMS’s SmartGrind system — a ground-breaking robotic crawler designed to tackle weld defects at an early stage. The device is deployed in hard-to-reach areas of renewable and traditional energy structures, where weld flaws can lead to catastrophic failures, leaks and costly shutdowns.

Based in Essex, OMS is a leading measurements, inspection and remediation specialist serving the energy sector. For SmartGrind, the company required gears that could deliver strength and reliability under extreme conditions, including severe weather, temperature fluctuations and continuous operation. The system must perform flawlessly in inaccessible environments and deliver critical functionality.

To meet these demands, RA Rodriguez supplied spiral bevel gears from its exclusive partner,

KHK — a long-established Japanese manufacturer. The gears are hardened for wear resistance and precision ground after heat treatment to improve accuracy and surface finish. This process enhances durability, reduces noise and vibration, and extends service life.

Jack Parlane, chief design engineer at OMS, said: “OMS uses KHK gears from RA Rodriguez in our proprietary grinding system gearbox. Our grinding system is groundbreaking technology that uses a robotic crawler to deploy targeted smart remediation services within pipelines, particularly to areas that are hard to access.”

Improving worker safetySmartGrind is a modular add-on to OMS’s AUGA.node visual and laser inspection system. It identifies and corrects weld defects early, ensuring rapid remediation and compliance with project specifications. Using a mounted flap disc, SmartGrind shapes welds to improve coatability and structural strength. It can repair issues such as spatter and excess penetration before re-scanning to confirm weld quality. The system can operate via a robotic crawler or attach to the ILUC (Internal Line-Up Clamp), eliminating the need for human intervention in hazardous environments and improving worker safety.

Mr Parlane concluded: “Maintaining strength and reliability are vital for our services, which operate in critical energy production environments, so KHK gears were the ideal choice for us. RA Rodriguez provides the high levels of customer service we require.”

Following collaboration with RA Rodriguez and the integration of KHK’s precision-engineered gears, OMS has delivered a robust and reliable SmartGrind solution. The technology exemplifies how engineering innovation is driving progress in the energy sector — enabling early-stage weld remediation that improves structural integrity, enhances safety and reduces downtime.