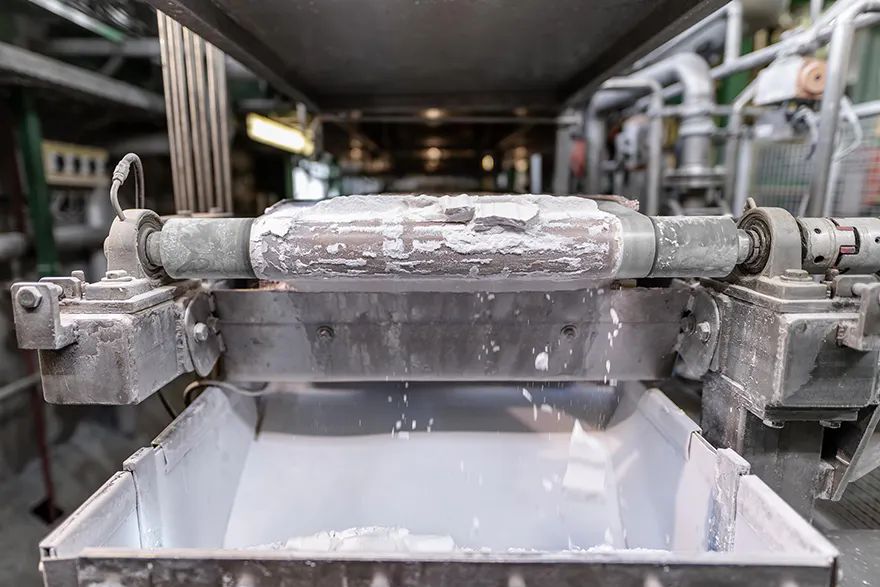

Several physical and chemical treatments are necessary to produce high-purity APW

Several physical and chemical treatments are necessary to produce high-purity APWRaw materials are finite — a reality that continues to drive manufacturers toward sustainable solutions. Mechanical engineering faces the challenge of balancing productivity with energy efficiency and resource conservation, without compromising quality. This principle applies equally to the recycling of solid carbide tools used in production.

Walter, the cutting tool manufacturer based in Tübingen, is a pioneer in this field and works closely with

Wolfram Bergbau und Hütten AG, Austria’s leading powder manufacturer, to keep tools within a closed cycle.

Walter’s sustainability strategy begins at the development stage, ensuring that raw materials are used responsibly by considering recycling throughout the tool’s life cycle. Before tools are recycled, Walter reconditions them for multiple use by regrinding, re-coating and restoring performance. This approach significantly extends tool life, reduces acquisition costs and conserves rare resources.

When tools eventually reach the end of their life cycle, Walter offers customers an online recycling portal to obtain quotes, order free containers and arrange collection. This guarantees that used tools are channelled exclusively into new tool production.

Chemical recycling methodThe recycling process then moves to Wolfram Bergbau und Hütten AG, a global leader in tungsten carbide powder production. Wolfram employs a chemical recycling method to recover high-purity ammonium paratungstate (APT), the key intermediate for tungsten carbide manufacturing. The recycled APT matches the purity and physical properties of material derived from primary raw sources, ensuring no compromise in quality.

Despite the complexity of chemical recycling, energy consumption is significantly lower than extracting tungsten from ore, which requires high temperatures and aggressive chemicals. Tungsten content in ore is 250-times lower than in solid carbide, making recycling far more efficient. Overall, the process reduces CO

2 emissions by more than 40%.

Annegret Bicherl, vice president of operations at Wolfram, said: “The recycling process requires less energy and has a lower CO

2 footprint than production from raw materials. Recycling is therefore clearly the future. By optimising the value-added cycle, we ensure sustainable energy efficiency and waste reduction.”

Walter uses recycled carbide powder to produce indexable inserts containing up to 60% recycled material. However, quality remains paramount. Stefan Rudolph, head of product development at Walter, explained: “It is crucial for us that the cutting tool materials are of impeccable quality. We do not even ask what percentage of the solid carbide powder comes from recycled material, and we do not see any indication of this. The machinist using the new Walter tool notices no difference — and that is exactly how it should be.”

Walter’s closed-loop approach demonstrates how sustainability and high-performance engineering can go hand in hand, setting a benchmark for responsible manufacturing in the machining industry.