As we enter 2026, future-proofing a manufacturing operation is more critical than ever. Optical metrology is essential for achieving micro-level precision and maintaining zero-defect quality through fast, non-contact measurement. Market Harborough-based

Optimax Imaging Inspection and Measurement Ltd offers a wide range of metrology solutions designed to enhance inspection and product development. Among the extensive catalogue of products available are two key solutions to help level up quality assurance today.

Level 1: Digital clarity on the benchtop with the EVO Cam IIThe EVO Cam II digital microscope is a useful upgrade from traditional stereo microscopes. This instrument can bring high-definition inspection to every operator's bench. Unlike traditional stereo microscopes it does not use eyepieces providing fast, comfortable ergonomic inspection and basic measurement.

Delivering Full HD imaging at 60 frames per sec and offering up to 300× optical magnification, it ensures exceptional clarity for detailed component analysis. Features such as automatic focus stacking, on-screen measurement tools, and live image comparison streamline quality control processes. With flexible connectivity options including USB, HDMI, and optional Wi-Fi, plus ergonomic stands and lighting accessories, EVO Cam II combines accuracy, speed, and ease-of-use — making it an ideal solution for electronics, automotive, aerospace, and the precision engineering sectors.

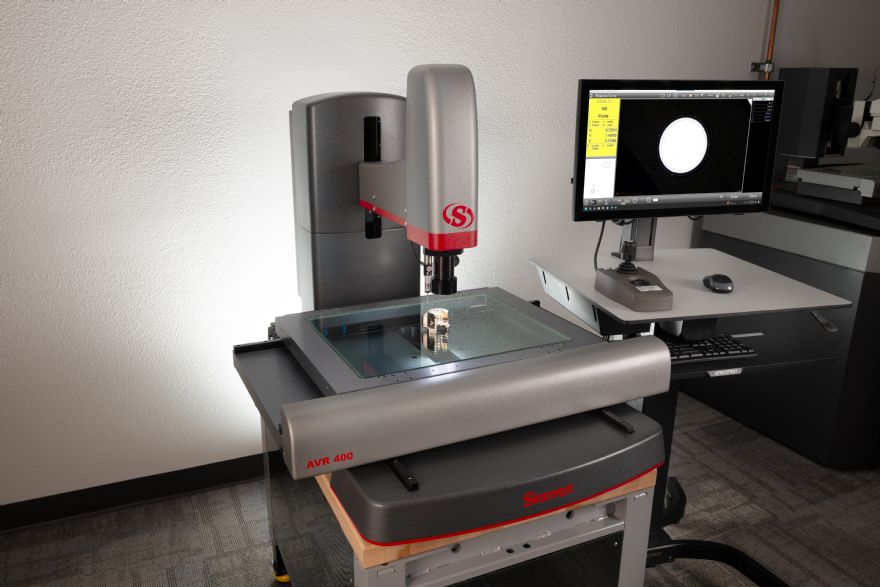

Level 2: Automated three-axis measurement with the Starrett AVR400 Vision SystemIf the EvoCam is not sufficient in terms of measurement and the need is for repeatable, high-accuracy dimensional measurements, the Starrett AVR400 CNC Vision Metrology System is an ideal solution. With this system it is easy to automate complex 2-D and 3-D measurements and it allows users to simply place an object on the stage and select the appropriate program for automatic measuring. Its a large-format CNC vision metrology solution designed for high-precision inspection of bigger components.

With a 400 × 300 × 200mm measurement envelope, it combines advanced optics — including 12:1 zoom and telecentric lenses — with MetLogix M3 software for automated measurements, CAD comparison, and intuitive touch-screen control. High-speed X-, Y-, and Z-axis motion ensures fast throughput without compromising accuracy.

Built on a granite base for stability, the AVR400 offers optional Renishaw scales for sub-micron resolution and touch-probe integration for hybrid tactile and vision measurements. Its programmable LED lighting and robust design make it ideal for demanding manufacturing and quality control environments, delivering speed, repeatability, and precision for larger and complex components.

Demonstrations are available on the full Optimax product range at the website

here.