norelem

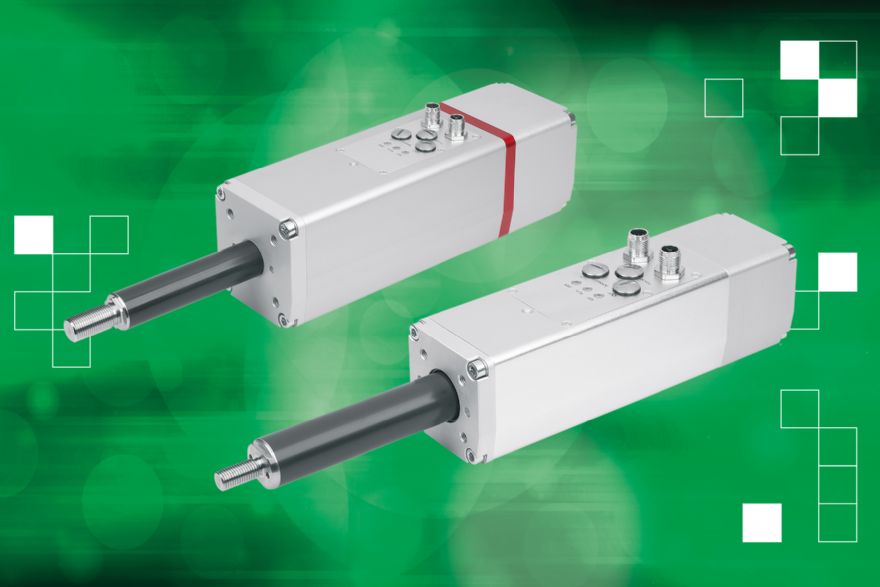

norelem has expanded its product portfolio with the introduction of new electric cylinders equipped with integrated IO‑Link servo technology. Developed as a compact, energy‑efficient alternative to pneumatic cylinders, the actuators offer precise linear motion for use in mechanical engineering, medical technology and automated production environments.

Each unit incorporates a brushless servo motor, servo controller and recirculating ball spindle within a single housing. Through the IO‑Link interface, setpoint values can be transmitted in real time, allowing speeds, accelerations and positions to be adjusted dynamically, even during complex positioning routines. The cylinders do not require any additional space in the control cabinet, and both speed and force limitations can be set directly via an external twist knob. Their ISO 15552‑compliant design ensures compatibility with existing brackets, connection components and accessories, simplifying integration into established systems.

Almir Jakupovik, sales director at norelem, said: “With efficiency and digitalisation shaping modern machine design, engineers are increasingly looking for alternatives to pneumatic systems that offer greater control and long-term performance. Our new electric cylinders meet these demands. By combining compact mechanics with IO-Link intelligence, they deliver precise, adaptable and data-rich motion control for a wide range of engineering applications.”

The cylinders are offered in two sizes to suit different application requirements. Size 60 models are available with spindle pitches of 5 or 10 mm, stroke lengths of 100, 150, 200 or 300mm, speeds up to 600 mm/s and forces up to 800 N. Size 80 versions feature a 5 mm spindle pitch, stroke lengths of 100, 200 or 300 mm, speeds up to 300mm/s and forces up to 1,500N. Both sizes operate at 24–48 V and provide a service life of up to 10,000 km or 20,000 operating hours.

Typical applications include automated assembly machinery, testing equipment, production systems and medical devices, where repeatable positioning, variable speed control and low‑maintenance operation are essential. The IO‑Link interface further supports users by enabling rapid parameterisation, performance monitoring and diagnostics directly from the controller, giving engineers greater oversight of system behaviour.

Compared with pneumatic cylinders, the electric units offer higher positional accuracy, improved energy efficiency and greater installation flexibility. They require only power and IO‑Link connections, and with fewer wear components than pneumatic systems, they demand less maintenance over their operating life. Their self‑inhibiting behaviour when stationary also helps to reduce energy consumption during operation.