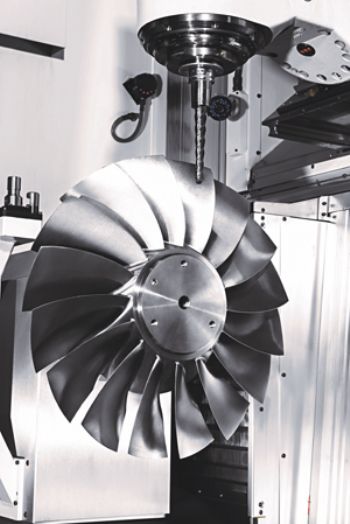

#ukmfg #engineering #AMRC #aerospace The Starrag Group recently gave UK aerospace OEMs and top-tier suppliers an insight into the extent and depth of the company’s on-going development programme relating to improvements in aerofoil blade/blisk milling.

Trials at Sheffield’s Advanced Manufacturing Research Centre resulted in significant progress in blisk machining using the new NB-series machine, which can achieve material removal rates of 1,000cm

3/min. They also demonstrated: the ‘adaptive milling’ of fan blisks and forged compressor blades; chatter-free machining of thin-wall airofoils; cryogenic cooling; and the machining of nickel-based super-alloy and gamma titanium blades.

A development of Starrag’s proven LX-series machines, the NB-series mill-turn machine is specifically designed for the machining of single- and multi-stage titanium and nickel-based super-alloy blisks of any shape — as well as steel blisks for gas turbines. It can accommodate workpiece diameters up to 1,100mm and blade lengths up to 200mm for machining via the tip entry route, where the tool is applied radially.

A multi-axis machine with X, Y, Z, A and B axes, it has a small footprint and features high stiffness and minimal compensation movement in X and Z for ultra-high dynamic capabilities, thanks to the low moving masses. The NB also features a highly dynamic B axis, which is positioned at 50deg to the spindle centre-line. Moreover, “the tool centre points meet all axes,” says Birmingham-based Starrag UK Ltd

(www.starrag.com).

Furthermore, the NB series is also under development as a twin-spindle unit featuring similar design parameters (including using the same coolant supply and chip removal route) but with separate tool-changers and independent axes and spindles for simultaneous yet independent machining. However, because all axes use the same

machine structure, the twin-spindle option represents significant savings in floor space and — importantly — in cost per spindle.

NB-series machines will be supplied by Starrag as a process-ready package, complete with the appropriate tooling, fixturing and automation.

Meanwhile, Starrag’s adaptive-milling routines have been developed to cope with the unique shape of each individual aerofoil; they are being applied successfully to both linear friction-welded blisks and precision forged blades. Each aerofoil/pocket is inspected by means of touch probing, and the resulting data is used to create unique NC programs/codes to achieve optimised blending. When it comes to the challenging process of machining thin-wall parts, Starrag has been researching the avoidance of chatter caused by friction between cutter and workpiece, by thermo-mechanical effects on chip form-ation and/or by the waviness of the workpiece surface.

The use of specially designed tools — such as tapered torus-type cutters rather than a tapered ball-nose design — in conjunction with simulation software to determine optimal cutting conditions, allows such tools to be applied at higher feed rates and spindle speeds. The result is reduced machining time, better surface finish and the elimination of premature tool wear.

Starrag’s investigations into tooling include the use of cryogenic cooling, where applying liquid CO2 to the centre of the cutting tool via the machine spindle dissipates heat and minimises both tool friction and swarf adhesion. Initial results have shown improvements of up to 70% in metal removal rates. Furthermore, the use of ceramic and carbide tooling (for roughing and finishing respectively) is providing a step change in the way Ni-based super-alloys can be machined.

Meanwhile, the machining of gamma titanium, which is increasingly being used as a lightweight high-temperature alloy, is also being investigated — with carbide tooling being applied at low cutting speeds but high depths of cut and high feed rates and with optimal cooling — including cryogenics.